In the ever-evolving landscape of corporate dynamics, the logistics of office relocations have become a pivotal aspect to consider. This article delves into the intricacies of corporate office moves from a supply chain perspective, shedding light on the crucial factors that ensure a seamless transition.

Continue reading “The Logistics of Corporate Office Moves!”Category: Supply Chain Management

The Supply Chain Renaissance Readiness Poll!

We believe that we are on the verge of a Supply Chain Renaissance. A period of time in which people, technologies, cultural demands and amenability, and motivation will all conspire to launch a long period of rebirth in Supply Chain.

While we discuss what this means in our article “The Supply Chain Renaissance Has Begun“, we thought we would conduct a poll amongst our readers to understand their readiness for this period of renewal.

Here we present, and interpret, the results of our polling.

Continue reading “The Supply Chain Renaissance Readiness Poll!”Pain Points – An Opportunity to Innovate and Expand!

Pain points are a part of business. They create opportunities to innovate, diversify and grow. Without customer pain points, there is no reason to be in business. Trading goods and services is as old as mankind itself.

Continue reading “Pain Points – An Opportunity to Innovate and Expand!”Social Media Tips for Supply Chain Leaders!

For busy executives, being active on social media and leveraging social media tips is kind of like networking. It’s one of those things that everyone says you absolutely have to do to benefit your career, but it’s hard to make it part of your daily routine.

Let’s be honest: it’s even harder for those who came of age before social media became ubiquitous. It can be tough to pin down what channels you should be on, what you should be posting, and the specific ways that a strong social media presence will bolster your career.

Continue reading “Social Media Tips for Supply Chain Leaders!”The Supply Chain Detective™ and The Case of the Missing Cash!

We were tremendously excited!

We had just completed the acquisition of a company that had great, complementary technical capabilities, a broader geographic footprint, new customers, and accretive profitability.

The CFO and I took over day to day management of the acquired company. A few weeks after the excitement of the acquisition had died down the CFO called me into his office.

“We are out of cash. Next week we have to decide to either pay the employees or pay our suppliers. We don’t have enough cash to do both.” How could we be missing cash?

We were in trouble.

What happened to the cash? How were we going to become solvent again and keep the business afloat for the long term?

It was another case for the Supply Chain Detective™!

Continue reading “The Supply Chain Detective™ and The Case of the Missing Cash!”Supply Chain Collaboration – The New Way to Drive Value!

Supply chain collaboration is a hot topic today and no wonder: companies that collaborate effectively across the supply chain have enjoyed dramatic reductions in inventories and costs, together with improvements in speed, service levels, and customer satisfaction.

Supplier chain collaboration itself isn’t new. What’s new is that it’s taken on a much greater urgency and importance.

Continue reading “Supply Chain Collaboration – The New Way to Drive Value!”The Supply Chain Detective™ and the $25M Robbery!

The company I had just joined was only a few months away from completing a multi-year project to revamp their primary Distribution Centre. The project would cost a total of $25 million, which seemed like highway robbery.

Part of my job was to see the implementation of the project brought to a successful conclusion, reaping all of the anticipated benefits.

But as I worked through the pains of a new system implementation, and gained more first hand knowledge, it occurred to me that the system design was completely lacking in strategic value.

Had the company just had a robbery of $25 million? This was a case for the Supply Chain Detective™.

Continue reading “The Supply Chain Detective™ and the $25M Robbery!”Future of Energy for Manufacturing!

Today manufacturers must continually look for waste reduction, process improvement and supply chain efficiency to meet competitive pressures and their customers’ cost reduction requirements for the future of energy. Programs such as Lean have become a popular means to develop a culture of simplification and constant improvement.

Although Lean principles provide an excellent basis for managing energy costs, such costs are often left out of an efficiency drive…

Why is that?

Continue reading “Future of Energy for Manufacturing!”To Infinity and Beyond! Ultimate Principles for Creating a World Class Team!

The Supply Chain team was generally viewed as lacking in skill and capability by those outside the organization. Customers and other internal functions viewed Supply Chain as a dysfunctional organization as evidenced by the poor Supply Chain performance metrics. And external benchmarking placed our Supply Chain last amongst our competitors. Going to infinity and beyond was a tall task to say the least.

Inside the Supply Chain organization there were a lot of very smart people. But there was no trust, teamwork or synergy. The culture was one more of complacency than of trend setting. And there was a lack of inspired leadership.

Something had to change!

Continue reading “To Infinity and Beyond! Ultimate Principles for Creating a World Class Team!”The Supply Chain Detective™ and the Mystery of the S&OP Phantoms!

The company had no formal S&OP (Sales and Operations Planning), or SIOP (Sales, Inventory and Operations Planning) process. The ability to forecast or track performance was sporadic and haphazard.

The CEO had mandated the implementation of a new S&OP process. An expert in S&OP implementation and operation had been hired to get this process in place.

But month after month the progress in getting a S&OP process in place was reported as either slow or stalled. Yet everyone on the Executive team voiced their support for S&OP. Still nothing happened.

What was really going on? What phantom was getting in the way of forward progress on getting S&OP in place?

This was another case for The Supply Chain Detective™.

Continue reading “The Supply Chain Detective™ and the Mystery of the S&OP Phantoms!”How Data Analytics Boost SOCI Compliance in Supply Chains!

In today’s interconnected world, securing critical infrastructure is paramount to safeguarding national interests and ensuring the uninterrupted flow of goods and services.

The Security of Critical Infrastructure Act (SOCI) represents a pivotal legislative framework designed to fortify the resilience of vital systems against emerging threats. Within this framework, supply chains emerge as a focal point for bolstering security measures, given their intricate network of dependencies and vulnerabilities.

Continue reading “How Data Analytics Boost SOCI Compliance in Supply Chains!”Immediate Retailer Actions to Overcome Logistics Delays!

We are fast approaching the Holiday season. Retailers would normally already have their goods on hand in Distribution Centres, Stores, and any other channels they may use.

But this year is different. The fallout from the global pandemic persists and shipping delays are rampant. Retailers should have had their goods by now yet for some their inventory hasn’t even left the country of manufacture. Even Christmas trees will be in short supply.

Panic should be setting in now if it hasn’t already. What are the options for Retailers to circumvent these logistics delays and get their inventory on hand in time for Holiday sales?

The State of Things

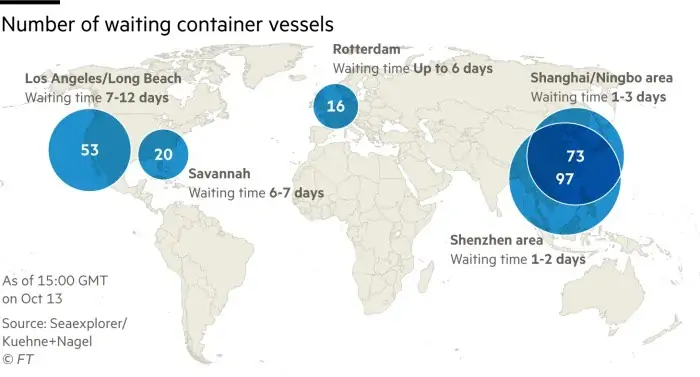

As reported by CNN on October 19, 2021, there are over 200,000 shipping containers waiting off the coast of Los Angeles, representing a backlog of over 2 weeks worth of work. That is notwithstanding the trail of additional ships and containers that are still on their way to Los Angeles.

Extending work hours at the port to a 24 hour schedule is alleviating some of the backlog but increased demand for products means that port workload will be heavy for some time to come. These backlogs and delays are not unique to Los Angeles as other ports in the US, Europe and Asia are experience similar problems.

The Financial Times states that as of October 15, 2021 there are 584 container ships stuck outside ports worldwide, double that of the same time last year.

These delays invariably lead to dramatic increases in shipping costs, which inevitably are going to work their way through to price increases for end consumers.

Even when those containers are unloaded another problem awaits. Getting enough trucks, and truck drivers, delays the pick up of these goods for delivery to parts unknown. The American Trucking Association has stated that there is a shortage of 80,000 truck drivers. The Coronavirus has dramatically worsened what was already a bad situation in terms of the shortage of drivers.

Any way you look at it Retailers are going to have a hard time getting all of the inventory they need to satisfy the surging demand, which will only be compounded when considering even greater demand driven by the Holiday season.

And in many respects this demand is perishable. Consumers will either go to other retailers who do have the inventory, or they won’t buy at all.

What are the drastic steps that Retailers can take NOW, to get as much inventory as possible into their channels?

Act Like It’s An Emergency, Because It Is!

In Retail the enormous wave of activity hits Supply Chain well before the Holiday season, as the massive influx of inventory hits the logistics channels and distribution centres. Normally by late October all of these goods would be on hand, in inventory, and positioned for the pending sales season.

Because so many Retailers are still waiting for goods that are stuck either on the ocean, in ports, or on the road, they must take DRASTIC steps now in order to mitigate any delays.

Here are our recommendations on steps that must be taken right now:

1. Put Your Team on High Alert

Create a SWAT team and a war room, with daily, if not hourly, governance and oversight. This is not a drill. Hire in extra outside consultants or resources as needed. There are lot of professional organizations offering Supply Chain as a Service (SCaaS). You need people working on this stuff 24 hours a day for the foreseeable future. If you don’t add extra resources now you will regret it later.

2. Spend MORE on Logistics

Plan to spend a lot more money on logistics, at least in the short term. Shipping costs are going up. PERIOD. Beyond that you should prepare your organization to spend even more. Remember, if you can’t get the goods into your customers hands, that demand is likely perishable. So you must spend more to get those goods into position so that you can fulfill as much of that demand as possible.

3. Proactively Manage Everything, Buy Whatever You Can, and Take Control

Proactively manage all aspects of your logistics network. Do not just leave this up to your carriers. These carriers are serving a lot of different customers, all of whom are also commanding attention and demanding expediting, and you are just one. You must make the decisions.

Buy any and all available inventory at your local Distributors and Wholesalers. Even if this means you need to take last minute actions to update your merchandising plan and online promotions, having any inventory is much better than having no inventory at all.

4. Implement All Alternatives for Moving and Storing Your Goods

Consider all alternatives for moving your goods:

- Route the ships with your goods to less congested ports. Ensure these ports are working 24-7.

- Hire truck drivers, and trucks, on contract to pick up and transport your goods. Consider paying for team drivers so that your trucks never stop running.

- Charter airplanes and air freight your goods to their destinations.

- Hire extra carriers and rent (or buy) containers wherever possible.

- Establish local, mini “Pop-Up” distribution centres and storage facilities close to either the ports or your points of highest customer demand, to minimize the movement of goods. This should be done irrespective of where your current facilities are.

- Implement drop shipping and avoid sending your goods to centralized distribution centres. Drop ship your goods directly to stores, consumers and other distribution points and avoid excessive handling. Even if this means stores will have crowded backrooms, or trucks in their parking lot, that is a lot better than having inventory stuck in a distribution centre, at a port or on the road.

- Embrace a Touchless, or “Don’t Touch” paradigm in materials handling and storage. Forget your current processes and procedures. Moving materials multiple times and moving those goods on and off storage shelves is wasted activity. Especially when you are pressed for time you should eliminate all unnecessary handling and storage activities. The drop shipping model is an example of this new paradigm.

- Buy as much inventory as you can now, far in advance of demand, and beyond normal order and delivery lead times. While this may be too late for this coming Holiday season, strong demand will continue for the foreseeable future. At a minimum buy the strategic elements of your inventory now.

- Extend your delivery lead time parameters, as well as your order lead time parameters. Leave these exaggerated times in place until we are well past the point at which logistics delays are problematic.

Logistics Delays in Conclusion

Don’t just sit back and wait for your goods to arrive. This is not the time to be passive, complacent and indifferent.

Everyone is scrambling to get their goods all at the same time. That means that common resources (eg. ships, ports, trucks, truck drivers, distribution centres) are bottlenecks. Demand for these resources is far greater than the available capacity hence these logistics delays.

The result is that the people who are more aggressive, more creative and innovative, more determined, more organized, and yes more willing to spend money, will be more likely to get their goods earlier than you and everyone else.

Retailers are staring at the stroke of midnight with respect to getting their goods in place on time for the Holiday season. Take all measures, no matter how extraordinary, to bypass these logistics delays and get your inventory in your channels. Your share of your customer’s wallets, and your business survival, depend on it.

Copyright © Mortson Enterprises Inc. All Rights Reserved.

Logistics delays article originally published on October 26, 2021.

Ensuring Product Delivery Efficiency in the High-Stakes World of Online Casinos!

In the rapidly evolving world of online casinos, ensuring product delivery efficiency stands as a cornerstone for business success. It encompasses a series of strategic implementations that streamline processes, minimize risks, and optimize user experience.

This discussion delves into the critical components of achieving efficiency in product delivery within this high-stakes industry, highlighting innovative strategies and best practices.

The ability to deliver products efficiently is not merely about technical prowess; it also encompasses understanding customer needs, responding to market dynamics, and continuously enhancing the user experience to foster loyalty and trust.

Continue reading “Ensuring Product Delivery Efficiency in the High-Stakes World of Online Casinos!”Building Trust in Your Supply Chain: Effective Vetting Techniques for Reliable Partners!

Supply chain management demands more than just operational efficiency; it requires trust.

Establishing reliable partnerships within your supply chain optimizes operations and ensures resilience against potential disruptions. This article delves into practical vetting techniques that enhance trust and reliability with your supply chain partners.

Continue reading “Building Trust in Your Supply Chain: Effective Vetting Techniques for Reliable Partners!”The Digital Supply Chain Journey: Step 4 – Supplier Onboarding!

The foundations of any Digital Supply Chain is the real time, end-to-end electronic connectivity of every node and aspect of your Supply Chain. Unless your company is entirely self-sufficient this connectivity requires extensive and exhaustive Supplier Onboarding.

And this onboarding is not restricted to the first tier suppliers with whom you have direct contact. You must connect with second, third, and fourth tier suppliers, many of which you will often never have even heard of before.

And that is an enormous challenge, to say the very least.

Continue reading “The Digital Supply Chain Journey: Step 4 – Supplier Onboarding!”

EBOOKS HERE

EBOOKS HERE