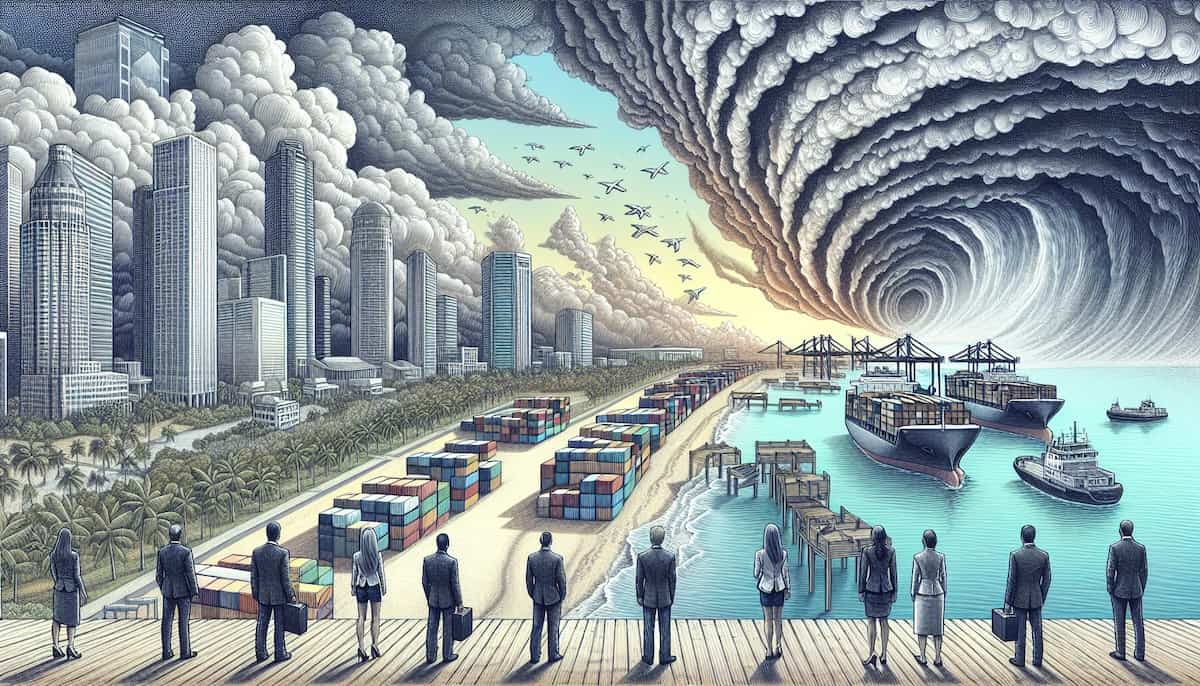

In today’s interconnected world, securing critical infrastructure is paramount to safeguarding national interests and ensuring the uninterrupted flow of goods and services.

The Security of Critical Infrastructure Act (SOCI) represents a pivotal legislative framework designed to fortify the resilience of vital systems against emerging threats. Within this framework, supply chains emerge as a focal point for bolstering security measures, given their intricate network of dependencies and vulnerabilities.

Continue reading “How Data Analytics Boost SOCI Compliance in Supply Chains!”

EBOOK HERE

EBOOK HERE