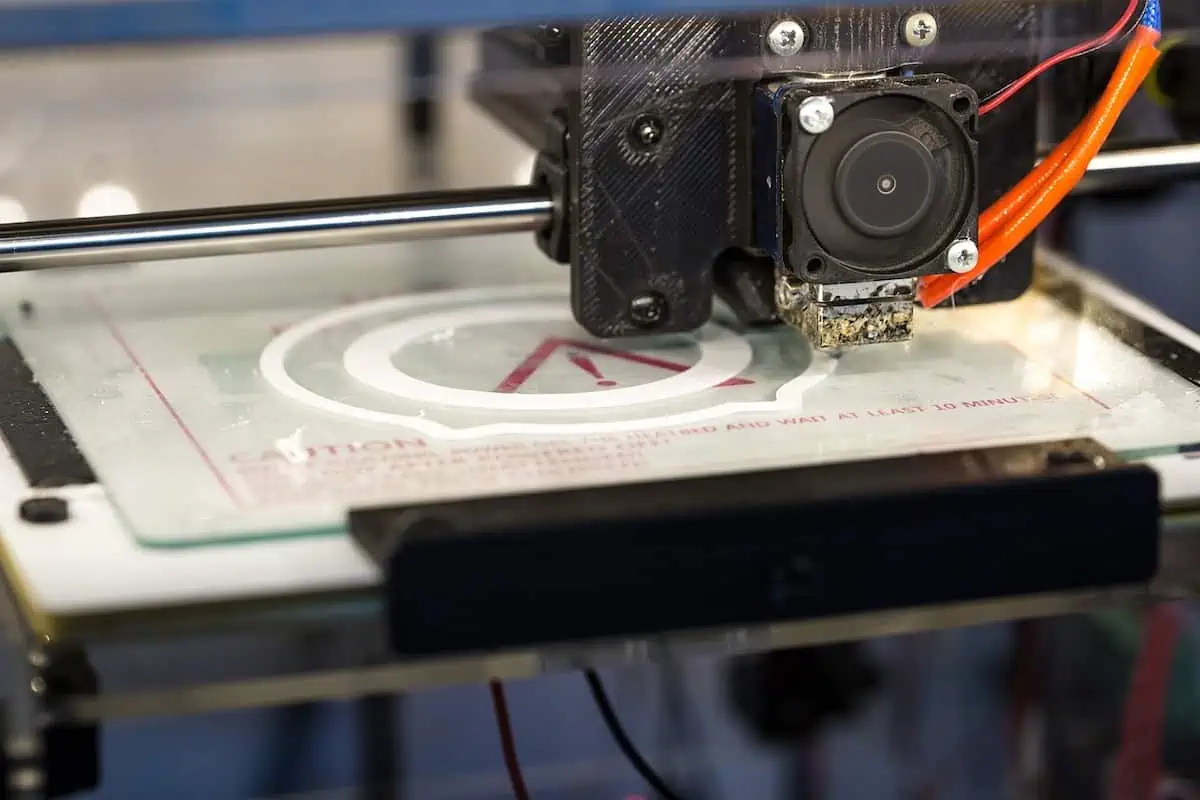

Although additive manufacturing and 3D Printing for both plastic and metal materials has been around for years, the investment, developments, breadth of applications, adoption rate, and beneficial case studies are expanding at an extremely rapid rate.

New processes, materials, devices, design applications, are emerging every day. Now, there are cloud sites that store portfolios of designs, much like Pandora does for music. All of this is creating an amazing amount of opportunity creating more efficient supply chains, new product types, de-centralized manufacturing schemes, and easier approaches to mass-customization.

Continue reading “Additive Manufacturing and 3D Printing!”

EBOOK HERE

EBOOK HERE