We are fast approaching the Holiday season. Retailers would normally already have their goods on hand in Distribution Centres, Stores, and any other channels they may use.

But this year is different. The fallout from the global pandemic persists and shipping delays are rampant. Retailers should have had their goods by now yet for some their inventory hasn’t even left the country of manufacture. Even Christmas trees will be in short supply.

Panic should be setting in now if it hasn’t already. What are the options for Retailers to circumvent these logistics delays and get their inventory on hand in time for Holiday sales?

The State of Things

As reported by CNN on October 19, 2021, there are over 200,000 shipping containers waiting off the coast of Los Angeles, representing a backlog of over 2 weeks worth of work. That is notwithstanding the trail of additional ships and containers that are still on their way to Los Angeles.

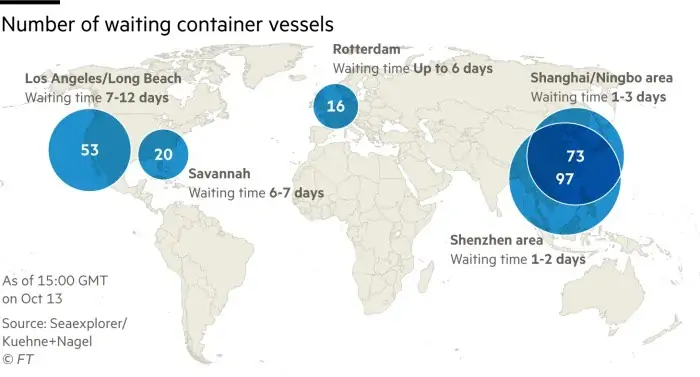

Extending work hours at the port to a 24 hour schedule is alleviating some of the backlog but increased demand for products means that port workload will be heavy for some time to come. These backlogs and delays are not unique to Los Angeles as other ports in the US, Europe and Asia are experience similar problems.

The Financial Times states that as of October 15, 2021 there are 584 container ships stuck outside ports worldwide, double that of the same time last year.

These delays invariably lead to dramatic increases in shipping costs, which inevitably are going to work their way through to price increases for end consumers.

Even when those containers are unloaded another problem awaits. Getting enough trucks, and truck drivers, delays the pick up of these goods for delivery to parts unknown. The American Trucking Association has stated that there is a shortage of 80,000 truck drivers. The Coronavirus has dramatically worsened what was already a bad situation in terms of the shortage of drivers.

Any way you look at it Retailers are going to have a hard time getting all of the inventory they need to satisfy the surging demand, which will only be compounded when considering even greater demand driven by the Holiday season.

And in many respects this demand is perishable. Consumers will either go to other retailers who do have the inventory, or they won’t buy at all.

What are the drastic steps that Retailers can take NOW, to get as much inventory as possible into their channels?

Act Like It’s An Emergency, Because It Is!

In Retail the enormous wave of activity hits Supply Chain well before the Holiday season, as the massive influx of inventory hits the logistics channels and distribution centres. Normally by late October all of these goods would be on hand, in inventory, and positioned for the pending sales season.

Because so many Retailers are still waiting for goods that are stuck either on the ocean, in ports, or on the road, they must take DRASTIC steps now in order to mitigate any delays.

Here are our recommendations on steps that must be taken right now:

1. Put Your Team on High Alert

Create a SWAT team and a war room, with daily, if not hourly, governance and oversight. This is not a drill. Hire in extra outside consultants or resources as needed. There are lot of professional organizations offering Supply Chain as a Service (SCaaS). You need people working on this stuff 24 hours a day for the foreseeable future. If you don’t add extra resources now you will regret it later.

2. Spend MORE on Logistics

Plan to spend a lot more money on logistics, at least in the short term. Shipping costs are going up. PERIOD. Beyond that you should prepare your organization to spend even more. Remember, if you can’t get the goods into your customers hands, that demand is likely perishable. So you must spend more to get those goods into position so that you can fulfill as much of that demand as possible.

3. Proactively Manage Everything, Buy Whatever You Can, and Take Control

Proactively manage all aspects of your logistics network. Do not just leave this up to your carriers. These carriers are serving a lot of different customers, all of whom are also commanding attention and demanding expediting, and you are just one. You must make the decisions.

Buy any and all available inventory at your local Distributors and Wholesalers. Even if this means you need to take last minute actions to update your merchandising plan and online promotions, having any inventory is much better than having no inventory at all.

4. Implement All Alternatives for Moving and Storing Your Goods

Consider all alternatives for moving your goods:

- Route the ships with your goods to less congested ports. Ensure these ports are working 24-7.

- Hire truck drivers, and trucks, on contract to pick up and transport your goods. Consider paying for team drivers so that your trucks never stop running.

- Charter airplanes and air freight your goods to their destinations.

- Hire extra carriers and rent (or buy) containers wherever possible.

- Establish local, mini “Pop-Up” distribution centres and storage facilities close to either the ports or your points of highest customer demand, to minimize the movement of goods. This should be done irrespective of where your current facilities are.

- Implement drop shipping and avoid sending your goods to centralized distribution centres. Drop ship your goods directly to stores, consumers and other distribution points and avoid excessive handling. Even if this means stores will have crowded backrooms, or trucks in their parking lot, that is a lot better than having inventory stuck in a distribution centre, at a port or on the road.

- Embrace a Touchless, or “Don’t Touch” paradigm in materials handling and storage. Forget your current processes and procedures. Moving materials multiple times and moving those goods on and off storage shelves is wasted activity. Especially when you are pressed for time you should eliminate all unnecessary handling and storage activities. The drop shipping model is an example of this new paradigm.

- Buy as much inventory as you can now, far in advance of demand, and beyond normal order and delivery lead times. While this may be too late for this coming Holiday season, strong demand will continue for the foreseeable future. At a minimum buy the strategic elements of your inventory now.

- Extend your delivery lead time parameters, as well as your order lead time parameters. Leave these exaggerated times in place until we are well past the point at which logistics delays are problematic.

Logistics Delays in Conclusion

Don’t just sit back and wait for your goods to arrive. This is not the time to be passive, complacent and indifferent.

Everyone is scrambling to get their goods all at the same time. That means that common resources (eg. ships, ports, trucks, truck drivers, distribution centres) are bottlenecks. Demand for these resources is far greater than the available capacity hence these logistics delays.

The result is that the people who are more aggressive, more creative and innovative, more determined, more organized, and yes more willing to spend money, will be more likely to get their goods earlier than you and everyone else.

Retailers are staring at the stroke of midnight with respect to getting their goods in place on time for the Holiday season. Take all measures, no matter how extraordinary, to bypass these logistics delays and get your inventory in your channels. Your share of your customer’s wallets, and your business survival, depend on it.