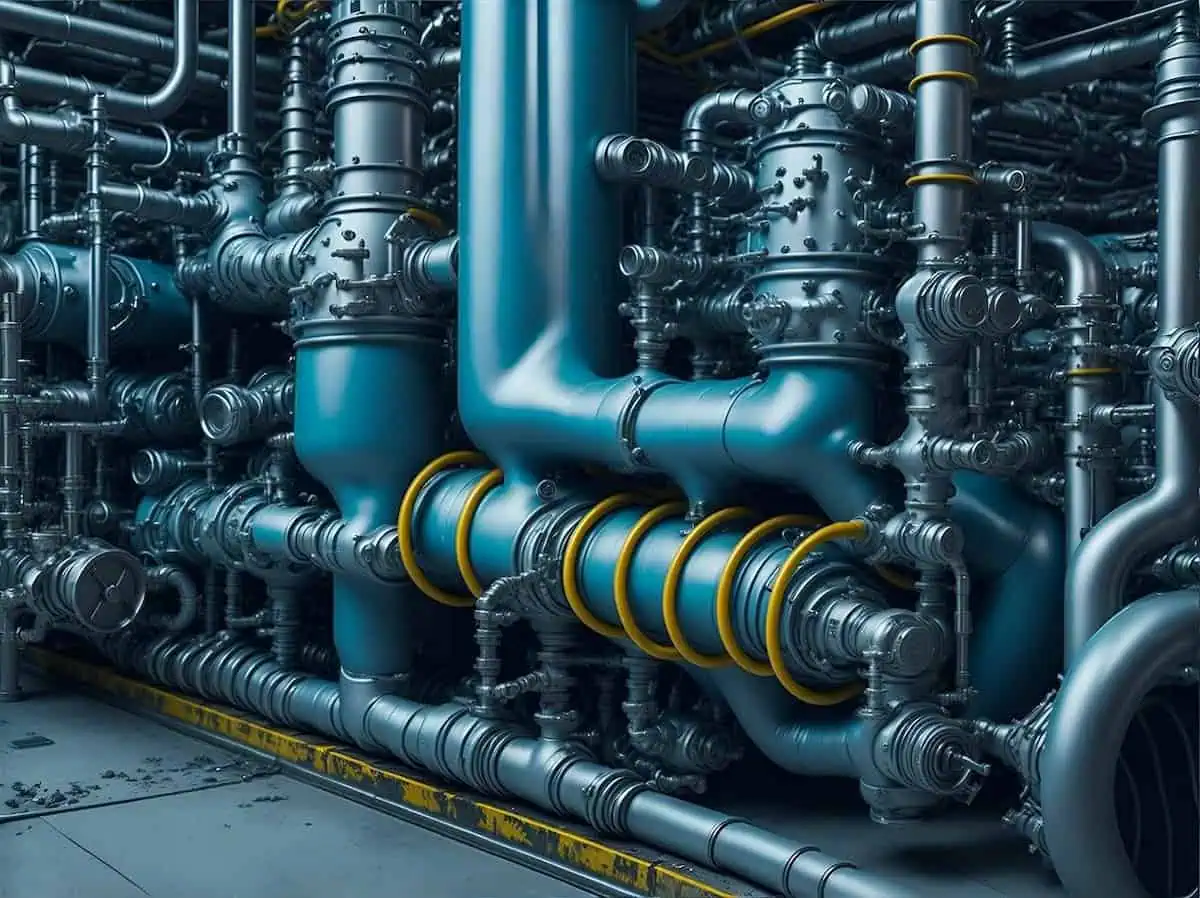

Manufacturing maintenance jobs are critical to the smooth and efficient operation of production facilities. These roles are vital in ensuring that machinery and equipment run optimally, minimizing downtime and maximizing productivity.

In an industry where time truly equates to money, the importance of maintenance cannot be overstated. This article explores the various facets of manufacturing maintenance, with a particular focus on the essential task of air leak testing.

Continue reading “The Importance of Manufacturing Maintenance Jobs!”

EBOOK HERE

EBOOK HERE