For most manufacturing operations, there are two fundamentally different approaches to maintenance: preventive vs predictive maintenance.

Most manufacturing and warehouse operations default to preventive maintenance, but a more tailor-made approach comes from predictive maintenance.

Preventive maintenance is a well-established strategy that has been around for quite some time. The philosophy behind this maintenance approach is simple: perform routine maintenance to all equipment apart of a manufacturing operation at a regularly scheduled interval.

This interval is often dependent on elements like the run time of an operation’s equipment, the age of the equipment, and the available down time an operation can schedule.

On the other hand, predictive maintenance is a newer, more innovative strategy that has shown its advantages for manufacturing operations. The philosophy behind predictive maintenance is almost opposite that of preventive maintenance.

In this guide to condition monitoring, we’ll delve into what condition monitoring is and explore how predictive maintenance utilizes data and technology to proactively identify and address equipment issues before they lead to costly breakdowns.

Rather than having all of an operation’s equipment serviced at the same time, predictive maintenance uses data collected from the pieces of an operation’s equipment to signify when maintenance is necessary.

Sounds great, right? Except the systems necessary to collect this data are much more expensive to implement than what businesses would spend just opting into preventive maintenance.

While they might be more expensive on average, predictive maintenance systems are becoming easier to implement by the day. As the number of Internet of Things technologies that are made specifically for the manufacturing industry increase, so do the possibilities they present.

For example, these IoT technologies are able to provide equipment owners with in-depth reporting and analysis of performance and external data on their equipment. This in turns allows equipment owners to better predict when their equipment will fail and and what maintenance measures should be taken in order to prevent said failure and ensure greater efficiency over time.

As many equipment owners and managers have come to understand, however, is that predictive maintenance systems are not always the saving grace that they seem. For many manufacturing operations, the barriers to entry are much too high. These systems require highly customized technology platforms that employees must be trained to master.

For operations that have many moving parts, this can be difficult. Whether that be due to having to change the way existing employees look at equipment maintenance, or training new employees as new policies develop, there are bound to be significant challenges. If your organization has the capital available to invest, and you believe in the abilities of your employees to transition to these maintenance systems, predictive maintenance could likely be a great fit for your operation.

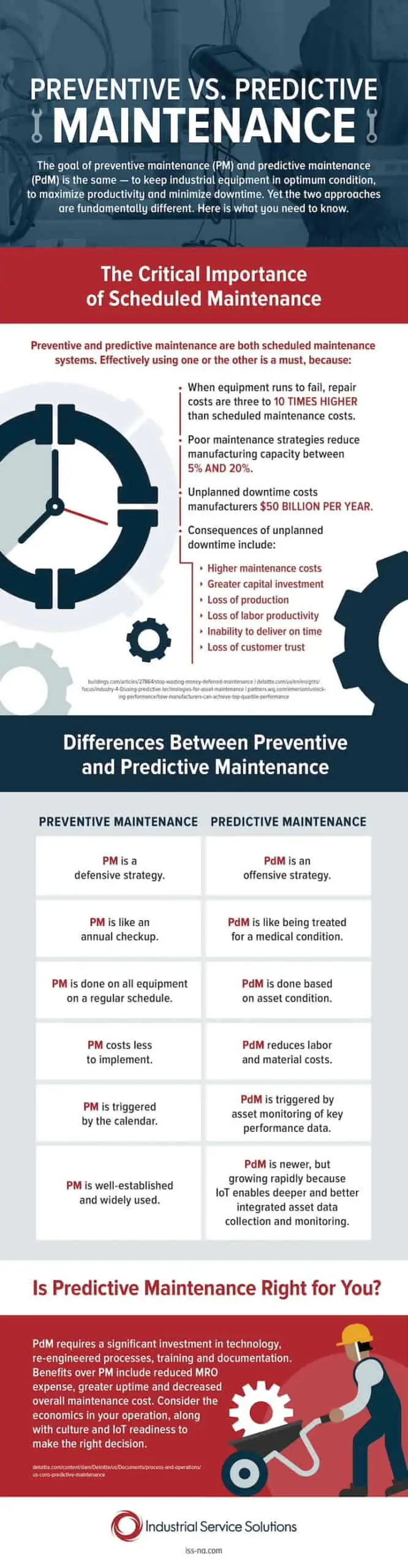

If you are considering beginning your own manufacturing business, it is important that you develop a maintenance strategy that is right for your operation. Whether that be preventive or predictive maintenance, the featured infographic below should be a great resource in helping you make the right call.

The infographic details the benefits and disadvantages of each system and how they relate to different manufacturing operations. Courtesy of Industrial Service Solutions.

EBOOK HERE

EBOOK HERE