The need for oil and gas on a global scale has grown during the last few decades. This is due to a number of factors, one of which being an increase in global economic activity. Here we present our Oilfields guide to Oil Field services.

Continue reading “The OilFields Market Guide to Oil Field Services!”Category: Industry

Cell Banking: Pioneering the Future of Biomedical Innovation and Preservation!

Cell banking is a groundbreaking development in the field of biomedicine, playing a critical role in research, therapeutic applications, and the preservation of biological diversity.

This comprehensive article delves into the multifaceted aspects of cell banking, providing a detailed analysis that goes beyond the coverage of similar content, enriched with data and unique insights.

Continue reading “Cell Banking: Pioneering the Future of Biomedical Innovation and Preservation!”Supply Chain Challenges in the Roofing Industry!

The roofing industry plays a crucial role in the construction sector, providing shelter and protection to homes and businesses. However, behind the scenes, roofing companies like Rapid Roofing Solutions, grapple with a myriad of challenges within their supply chains.

From the sourcing of raw materials to the delivery of finished products, the industry faces several hurdles that impact timelines, costs, and overall efficiency.

Continue reading “Supply Chain Challenges in the Roofing Industry!”4 Ways to Reduce Energy Grid Reliance!

The purpose of an energy grid is to provide more efficient electricity transmission, delivering power to residential, commercial, and industrial properties nationwide.

An energy grid consists of complex electrical systems that generate energy from various sources to quickly restore power after energy disturbances. Moreover, an energy grid can reduce utility operations, management costs, and consumer electricity bills.

Continue reading “4 Ways to Reduce Energy Grid Reliance!”What is a Vacuum Oven and its Applications?

Normally, we know about only a single type of oven that we use in our homes. But this equipment has multiple types depending on the nature of the work where it will be used. If you are working in any laboratory, especially with chemical compounds, you must have heard about a vacuum oven.

Have you ever thought about what is this equipment and how it is different from a standard oven? If you have been wondering to know about this type of oven, you will get your answer on this page.

In this blog, we are going to tell you what this oven is, its benefits, and its applications.

Continue reading “What is a Vacuum Oven and its Applications?”8 Professions with High Workers’ Comp Claim Rates!

Many professions are known for being incredibly hazardous. While many of the positions on this list seem like no-brainers, others tend to surprise people with how dangerous they can be.

For those that are curious, here are eight professions that have high workers’ comp claim rates throughout the United States. Some professions do have high compensation but do pose a lot of threat to safety. That is why hiring injury lawyers is a must in case someone gets involved in an accident, and in this case, during working hours.

Continue reading “8 Professions with High Workers’ Comp Claim Rates!”Advantages of Using Sealant-Free Solutions for Industrial Pipe Maintenance!

In industrial maintenance, the integrity of piping systems is crucial. Traditionally, sealants have been the go-to solution for sealing pipe joints and penetrations. However, the evolution of industrial maintenance practices led to the development of sealant-free solutions, offering many benefits over their traditional counterparts.

This article explains the advantages of using sealant-free solutions like Pipetite in industrial pipe maintenance, highlighting their impact on hygiene, durability, flexibility, installation ease, and environmental safety.

For those looking to make a switch to these innovative solutions, you can buy CSI Pipetites, which are a leading example of high-quality, efficient sealant-free products in the market.

Continue reading “Advantages of Using Sealant-Free Solutions for Industrial Pipe Maintenance!”Customising Nitrogen Solutions: Tailoring On-Site Generation Systems for Diverse Industries!

Nitrogen is required in several businesses within the realm of industrial processes, each with unique requirements and challenges. As unconventional methods of delivering nitrogen give way to more inventive ones, the concept of customising nitrogen-generating equipment for on-site usage has emerged as a game changer.

This article looks at the significance of changing nitrogen solutions and how companies are redefining how they satisfy nitrogen demands by making adjustments to on-site production systems for a range of industries.

Continue reading “Customising Nitrogen Solutions: Tailoring On-Site Generation Systems for Diverse Industries!”Innovations in Retaining Rings!

Retaining rings, also known as snap rings, are small circular fasteners used to securely hold components onto shafts or in housings. They are commonly used in industrial applications, such as automotive, aerospace, and manufacturing industries.

Over the years, innovations in retaining rings have had a significant impact on the supply chain, improving efficiency, reducing costs, and increasing reliability.

In this blog post, we will explore some of the latest innovations in retaining rings and their impact on the supply chain.

Continue reading “Innovations in Retaining Rings!”6 Different Brewery Supply Chain Issues and Solutions!

In the dynamic brewing industry, supply chain obstacles often complicate the journey from grain to glass. From sourcing premium raw ingredients to delivering each fresh pint to customers, breweries face a host of complex challenges.

As we unravel these issues together, you’ll gain insights into practical solutions devised to counter this logistical balancing act.

So tighten your seat belts for an enlightening exploration into the intricate brewery supply chain that keeps our beer mugs frothy!

Continue reading “6 Different Brewery Supply Chain Issues and Solutions!”What are the Best Building Materials?

The construction sector employs various building materials for construction projects. Every building material has strengths and weaknesses that you should take into account.

When balancing factors like cost, aesthetics, structural integrity, and longevity, engineers and architects frequently use a combination of these materials. Structural engineers advise architects on the load-bearing capacities of these materials in building projects. Every building material is suitable for different uses because of its distinct characteristics.

That said, here’s a list of the best building materials used in construction.

Continue reading “What are the Best Building Materials?”3 Ways to Control Motors for Precision Movement in Positioning Conveyors!

Industrial conveyors employ a variety of constituent components, primarily motors. For conveyors operating at constant or variable speeds, motors are adept at controlling their velocity. In this case, the main drive motors simply alter the velocity as per requirement.

However, positioning control has different parameters and requires motors that can start or stop the conveyor with high precision. The first thing to consider here is the type of motor. For positioning applications, a step or servo motor is a great choice.

Furthermore, it requires specific features and accessories to accurately start or stop the conveyor at the desired position. Three such ways for positioning conveyors are addressed below.

Continue reading “3 Ways to Control Motors for Precision Movement in Positioning Conveyors!”The Art and Science of Gold Smelting: A Deep Dive into the Process!

Gold smelting is a fascinating blend of art and science, an intricate process that transforms raw ore into gleaming gold bars. This transformation occurs in a specialised piece of equipment known as a furnace which plays a pivotal role in the process.

In this blog post, we’ll delve deep into the gold smelting process, exploring both its scientific and artistic aspects.

Continue reading “The Art and Science of Gold Smelting: A Deep Dive into the Process!”A Look at the Effects of Agricultural Inflation!

The current cycle of high inflation has affected nearly every industry in one way or another. One of the most notable sectors has been the cost of food. Food prices have soared over the recent year or so, and while it affects every consumer, it also affected every farmer first.

Let’s take a look at the ways in which the agriculture sector has been impacted by agricultural inflation and how they are coping.

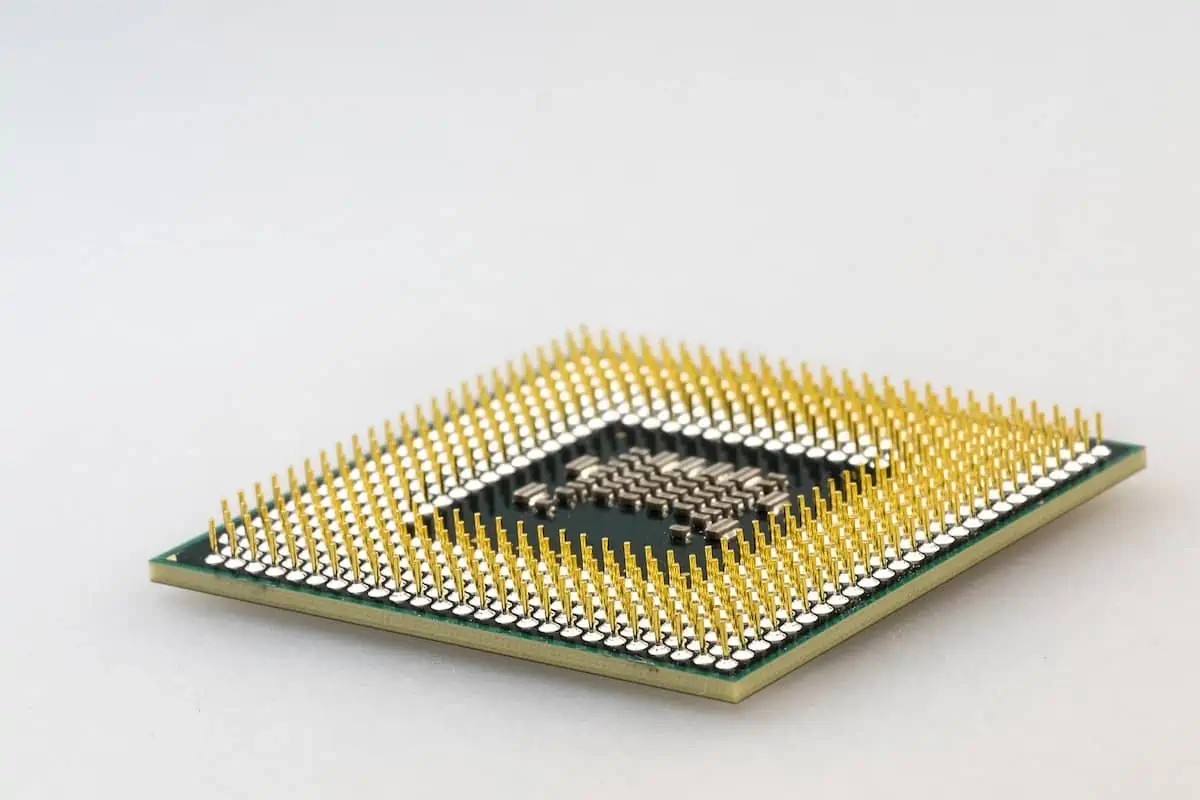

Continue reading “A Look at the Effects of Agricultural Inflation!”4 Industries Affected by the Global Chip Shortage!

The global chip shortage crisis started in the second quarter of 2020 during the Covid-19 lockdowns around the world, and it continues to be an ongoing problem.

During 2020, the demand for semiconductor chips, which are also known as integrated circuits, exceeded supply. The shortage affected a whopping 169 industries.

Continue reading “4 Industries Affected by the Global Chip Shortage!”