Sustainability is becoming an increasingly vital priority for businesses at every stage of the modern supply chain. Awareness is rising that inefficiencies and wasteful production processes can have a major negative environmental impact, and that addressing these problems should be central to the minimising of carbon footprints along the supply chain.

One of the key steps businesses are taking to improve the environmental profile of their production, distribution and shipping processes is to embrace sustainable packaging methods and technologies.

The reasons for this are clear: sustainable packaging is more cost-effective, better for the environment and more popular with consumers, and it aligns better with current regulatory demands.

In order to maximise the sustainability of their approach to packaging, businesses should therefore look to make full use of every technological advantage they can find.

Here, we will explore the reasons why businesses are investing in greener packaging solutions, and the ways that enhanced marking and coding technology can aid these efforts.

Why are businesses investing in sustainable packaging?

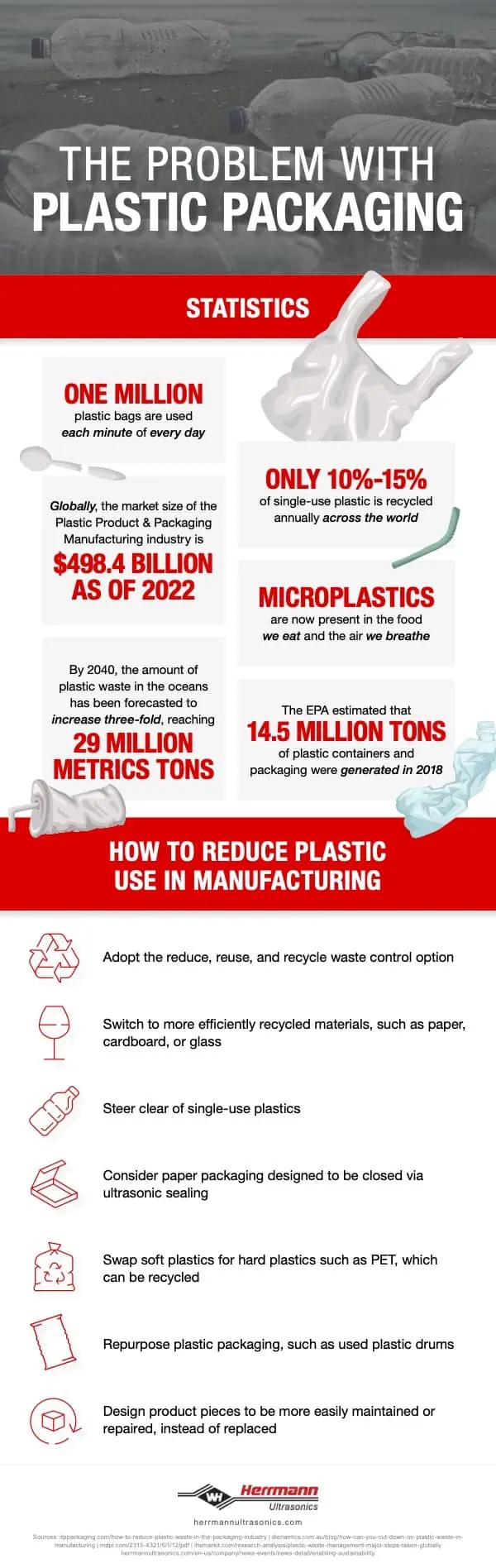

There are a wide variety of reasons why businesses involved in the production of physical products and goods are focused on improving their packaging sustainability at the moment. Numerous high-profile campaigns and initiatives have highlighted the impact of discarded packaging on the world’s oceans and landfills over the last few years.

This has led regulators to take action to incentivise change, and inspired a growing appetite among consumers for companies to take action.

In 2021, a report from Trivium Packaging indicated that 67% of consumers now feel it is important that the products they buy come in recyclable packaging, with 54% saying they factor this into their purchasing decisions and 70% saying they are willing to pay more for sustainable packaging. These figures are especially high among younger consumers, showing that this trend is likely to become more prevalent in future.

Businesses are therefore looking to make proactive changes to their packaging designs and production methods in order to achieve the following goals:

- Create more efficient packaging production methods that minimise wastage and energy consumption

- Make packaging smaller and lighter for easier and less expensive transportation

- Adhere to evolving regulatory requirements for environmental stewardship and carbon reduction

- Enhance their status as brands with a strong dedication to sustainable practices

How can marking and coding technology systems aid packaging sustainability?

There are various technological solutions that can contribute to better packaging sustainability, but many overlook the potential role that newer marking, coding and labelling systems can play in this.

Every business that creates packaging and labelling for its products relies on printers and marking technology to encode vital product data and information, such as barcodes, batch numbers, production details, sell-by dates or tracking ID numbers. This data is necessary to provide retailers, consumers, regulators and supply chain partners with essential safety, traceability and compliance data – as such, it makes sense to invest in ways of carrying this out more efficiently.

Demand for advanced coding systems optimised to deliver more sustainable performance is on the rise, with many businesses proving willing to pay higher upfront costs in exchange for the long-term benefits and return on investment these systems can provide. These include:

Eco-friendly inks

In the past, many of the inks used in product marking and coding were created using mineral oils and methylethylketone (MEK) – all of which have been linked to various environmental and greenhouse gas impacts during production and evaporation, as well as potential health issues when this type of ink is used in food packaging.

With regulators now recommending that mineral oil-based inks be removed from packaging production, modern systems offer alternative, eco-friendly options such as water, alcohol or vegetable oil-based inks, eliminating the environmental issues while maintaining the same level of performance.

Printing directly onto any type of packaging

Modern marking and coding equipment is able to print directly onto potentially challenging materials and packaging types, including printing barcodes and essential data on plastic and metal, or directly onto curved or irregularly-shaped items such as bottles.

This allows manufacturers to reduce packaging waste by eliminating the need for physical paper or plastic labels, while also making it easier to switch to thinner, lighter packaging by making it possible to print on even fragile surfaces.

Economical performance and automation benefits

Modern marking and coding technology incorporates numerous performance refinements and improvements to increase overall efficiency across the lifetime of the system, and is designed with sustainability in mind. Examples include longer-lasting print heads that require less regular replacement, overall reductions in energy usage, and cartridge designs that use every single drop of ink to minimise waste.

Additionally, since this technology is highly automated, production lines can run reliably without manual errors, with no need for regular stoppages or reactive maintenance. All of these improvements help to ensure a smoother and more efficient production process for packaging, as well as delivering energy savings, a reduced carbon footprint and lower costs.

Adopting a broad approach to packaging sustainability

To unlock the maximum environmental value across the supply chain, it is important for businesses to incorporate these enhanced marking and coding solutions alongside other investments in greener packaging, creating a holistic approach to packaging sustainability. Other potential interventions include:

- Making sure that packaging is recyclable or reusable wherever possible, or biodegradable and compostable when disposed of

- Ensuring that packaging can be easily recycled through standard channels, which is not always possible when using complex multi-material packaging

- Switching to lighter, more flexible materials when creating packaging

- Incorporating more recycled materials into packaging production

- Eliminating unnecessary packaging on some items

With the evidence suggesting that demand for sustainable packaging is only going to increase in the next few years, making these investments now should be considered a sensible long-term strategy.

Implementing these sustainable process improvements throughout the supply chain will ultimately help businesses to enhance the green credentials of their organisations, and contribute to the vital environmental stewardship objectives that every organisation in the world has a responsibility to meet.