Does anyone like being stuck in a Traffic Jam?

Prior to one Holiday season several years ago the volume that was coming into the Distribution Centre receiving area was unprecedented and unpredicted. We were out of room on the docks and we were out of storage space but trucks kept on coming. And we were still weeks away from being able to ship product to stores to relieve the pressure.

We were gridlocked. We kept inching our way along but we were very, very close to having this traffic jam of activity shut us down.

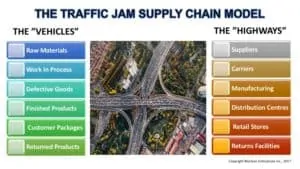

The Traffic Jam Supply Chain Model

Consider each of the nodes (suppliers, operations, distribution centres, stores) in your Supply Chain as being a “highway”. Consider also that all of the goods that you are moving along these nodes are the “vehicles” travelling on those highways. Your business growth means that more and more vehicles are going to be moving on those highways. And those highways only have so much capacity.

And unless you plan and manage your Supply Chain well you are going to end up with Traffic Jams on those highways especially at “Rush Hour”. The Black Friday/Cyber Monday period is a great example of a Rush Hour. This Rush Hour period will stretch your capacity to the limit. You will be out of capacity and everything will grind to a halt.

Any traffic jam will slow your Supply Chain, and your Company, to a snail’s pace, if not stop it altogether.

Managing the Highways

As your business grows you are moving more and more goods throughout your Supply Chain. Your supplier base is likely increasing and becoming more geographically diverse. Your operations will be increasingly stretched trying to cope with the heavier volume of activity.

Again let’s consider each of the nodes in your Supply Chain to be “highways”. By definition any highway only has so many lanes. It may be possible to add lanes, that is capacity, but this takes planning, time and resources. Those highways merge onto other highways. If you do not manage the transition well traffic will slow as you move from one highway to the next.

So how do you help prevent having a traffic jam on any of your highways? There are many techniques to consider within this model:

Add Another Highway

With enough planning, resource, and the need, you can add a new Distribution Centre for instance. You may also be able to have your Suppliers drop ship products directly to your customers. And if necessary you may want to dual source some of your supply with more than one supplier. Any of these techniques add highways, which increases capacity.

Add More Lanes To Your Current Highway

You may be able to add more capacity in your current facilities. This may mean adding a new shift, more equipment, or more staffing. It could also mean renting more storage space on a short or long-term basis. Adding capacity is like adding lanes to your highway.

Also consider “No-Touch” techniques such as cross-docking. It’s like adding a fast-moving carpool lane to your highway.

Remove The Potholes On Your Current Highway

Lean out your operation to increase efficiency, increase capacity, and reduce the time required to move goods through your facility. Focus on reducing defects and removing wasteful activities that slow down your operation. A more efficient highway means faster moving vehicles.

Avoid Lane Closures

If you lose capacity because a key piece of equipment is down, or you don’t have enough staffing, effectively you are losing a lane on your highway. It’s critical to have enough planning and contingency in place to deal with any issues quickly to avoid lane closures. Or if you do have a lane closure you need to get it back open fast!

All of these techniques will have the effect of increasing the number of vehicles you can handle on your set of highways.

Managing the Vehicles

All of your goods are the “vehicles” on those highways. Your company may be adding more parts, more finished goods, or taking many more customer orders. And your consumers, especially in E-Commerce, can number in the hundreds of thousands anywhere in the world. And the more vehicles you add to your highways the more congestion there will be.

So how can you improve the movement and flow of those vehicles to ensure an efficiently moving Supply Chain without interruption?

End To End Visibility Of Those Vehicles

If you do not have any planning or visibility to the vehicles that are, or will be, moving on your highways then you are driving blind. Having a Transportation Management System with electronic connectivity showing you where your goods are at any point in time gives you the ability to manage your product flow. Similarly an integrated Order Management System, Shop Floor Control System and Warehouse Management System are critical capabilities to provide you with that visibility.

These systems and that visibility will serve as traffic monitoring and control. An overall Control Tower for the Supply Chain will further allow you to schedule and modulate the movement of these vehicles.

Scheduling The Entry Of Those Vehicles On To Your Highways

The coordination of the timing at which vehicles enter your highways can make a huge difference in flow. You often do not need to have all of your vehicles enter the highway at once at Rush Hour.

Scheduling techniques such as Just-In-Time delivery or Line Balancing/Scheduling can make a huge difference in determining the timing and rate at which vehicles enter your highways.

Tow Broken Vehicles Off Of Your Highway Quickly

If you have goods that are defective you need to deal with them quickly and effectively. Dealing with broken vehicles on the highway means you need to work like a NASCAR pit stop to avoid traffic backing up.

Otherwise you need to move the vehicles off of your road to a repair station. But you do need to fix those vehicles quickly because they must get back on to the highway.

Rush Hour Traffic Jam Management

You will certainly face busy times of year. Black Friday/Cyber Monday is a prime example of a “Rush Hour”. The timing is set, you can’t change it, and a phenomenal number of vehicles (customer orders) are going to enter your highways in a very short period of time.

Many retailers tell customers when they should expect delivery of their product. Similarly many highways have overhead, electronic signage which tells vehicles how much time it will take to get to the next exit. Or the signage may have other important messages. It is important wherever possible to communicate expectations to your customers (vehicles). It may not mean that there are no rush hour delays but the awareness will hopefully reduce the amount of honking on the highway.

The key is to modulate when and where vehicles enter and move along and between your highways. Keep the flow going and address any issues quickly. And all of the techniques you use to manage your highways will help the movement of your vehicles.

The Traffic Jam Supply Chain Model Considered

You have to keep the traffic in your Supply Chain flowing uninterrupted at a very high-speed. If you have any kind of capacity constraint, interruption or slow down in your flow then traffic will become congested. It can in turn become a traffic jam which at its worst will cause your entire operation to become gridlocked.

There are many techniques which you can apply to improve the conditions of your highways and the flow of your vehicles. We have enumerated some of these techniques here.

Most importantly you need to proactively plan and manage your Supply Chain. That will give you the best chance of minimizing traffic jams and disruption to your business.