Imagine having virtually no raw material inventory on hand because all of the components and parts that you need can be made on demand.

Imagine having virtually no finished goods inventory on hand because you can make the products precisely when ordered in real time and have them personalized or customized to a customer’s individual specifications.

While this may sound far fetched the incredible advances in 3D Printing, or On Demand Manufacturing, are helping to bring these capabilities closer to the realm of possibility.

My History with 3D, On Demand, Printing

My experience with 3D Printing began when I joined a national retailer which focused on selling books. But additionally they were expanding their product offering to include a large number of items including toys and electronics.

A gentleman who joined the company the same day I did was going to be responsible for running the Toy business. He had just been recruited from a large, fast growing Toy manufacturer and distributor.

As he was setting up his office I noticed that he had a lot of cool items on display. One in particular was a plastic prototype toy of a figure from a popular movie. When I asked him about it he told me that it was created by a 3D printer.

They could create prototypes of any product in real time and make changes instantaneously and inexpensively. They didn’t need to pay for expensive molds and tools anymore. As such they were able to reduce their costs and reduce their time to market by weeks and months which gave them a tremendous competitive advantage.

I thought that was all so cool.

Later on as I met with the various suppliers to this retailer I visited one of their largest book distributors. Amongst other capabilities they had a massive operation dedicated to the on demand printing of books.

When you consider that there are literally millions and millions of books you realize that it is impossible for ANY retailer to carry at least one of each book in stock. And while the latest books sell in high volumes most of the skus are sold in quantities of one.

Every retailer would like to offer their customers an “endless aisle” catalog even though it is physically impractical to carry one of every title in stock. But this is where on demand printing comes into play.

That distributor was able to accept orders for individual quantities of any single book, print it on demand, and send it to customers in record time.

The result was that the company could fulfill the demand of any single customer for any single item anywhere in the world. And they could provide an “endless aisle” product offering without having to carry unaffordable and physically impractical levels of inventory.

The History and Scope of 3D Printing

It seems like 3D Printing is an exciting new technology. But the early concepts of this technology date back to the 1970s and 1980s.

The technology involves the creation of a digital model of the object to be created. This digital model is then “printed” layer by layer on a platform, which each succeeding layer building on the layer below it, to ultimately create a physical reproduction of the digital model.

The predominant printing material has been plastics but now this includes metals, glass, organic materials, and hybrid materials. And as the number and type of materials expands so do the potential applications.

The price point for 3D Printers has now dropped to the point where you can buy one for your home. It is no longer the exclusive domain of researchers and large companies.

Applications and Examples

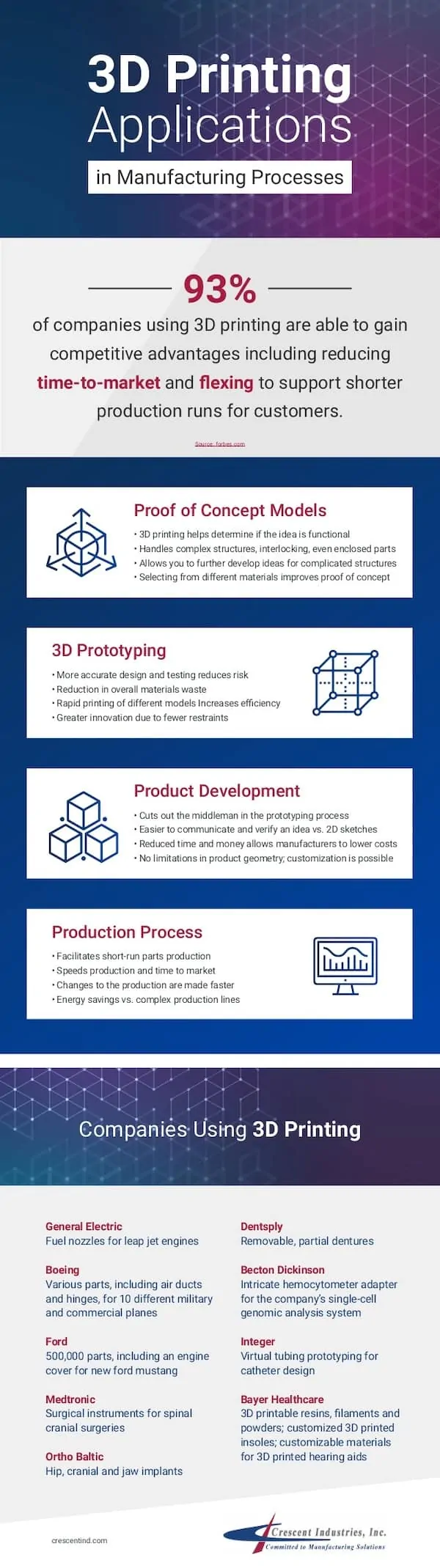

3D Printing continues to enable the provisions of products for every stage of the manufacturing process from prototyping to subassembly to end product.

It has application in a large number of industries including Manufacturing, Healthcare, Fashion, Aerospace, Automotive, Construction, Transportation, Education, Furniture, Toys, and Marketing.

And there are numerous examples of 3D Printed products including clothing, cars, houses and buildings, medical items (eg. prosthetics), food, circuit boards, jewelry, and dental devices.

What does this mean for Supply Chain?

As we stated in our opening comments 3D Printing, or On Demand Manufacturing, has tremendous potential for reshaping Supply Chain.

How many times have you needed quick prototypes, or even faster changes to prototypes? How many times have you been out of stock of a particular items which stops manufacturing and the fulfillment of customer orders. And how many times have you been unable to fill a customer order because you don’t carry that item in stock or you can’t get it in time?

Every Supply Chain professional has experienced these situations and more.

So the opportunity that 3D Printing, or as I prefer to say, On Demand Manufacturing provides to Supply Chain is huge.

It may certainly be an enormous leap forward but imagine if you were able to create prototypes, production parts, and personalized finished products on demand. You would lower costs, improve productivity, reduce inventory, increase revenue, generate customer satisfaction, and drive better cash flow and return on investment.

Conclusion

The potential for 3D printing to drive revolutionary change in Supply Chain is huge.

And there are real limitations in terms of technology, resources, infrastructure, costs and more.

But over time all of those limitations will fade away.

Visionary Supply Chain leaders will be looking to incorporate a 3D Printing (or Additive Manufacturing or On Demand Manufacturing) capability (whether insourced or outsourced) into their strategies going forward.

Everyone else will be left behind.

With the rise in technological advancements new technologies are adding on the 3D printing industry, also known as additive manufacturing.