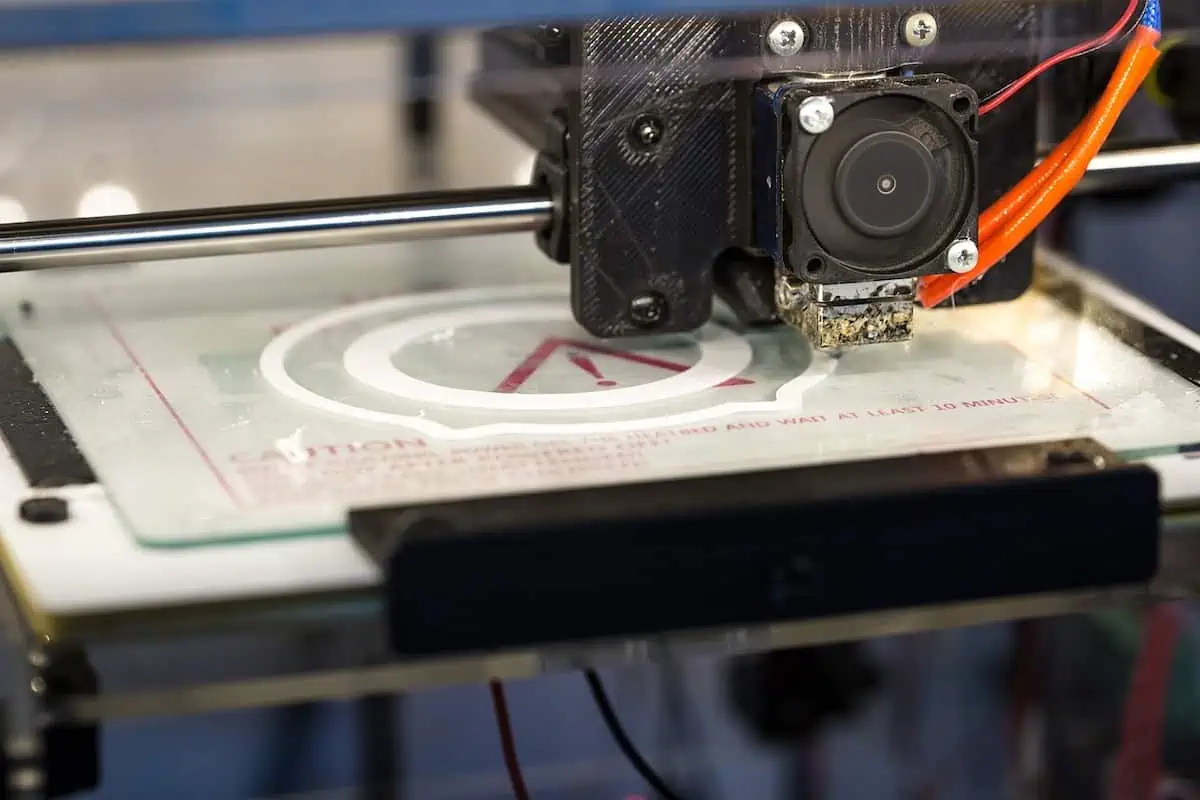

Have you ever wondered what it would be like to have a product idea and have it produced within hours? With 3D printing and on-demand manufacturing that idea can become a reality in practically no time.

“The speed at which 3D printing can produce a product is unparalleled,” says a report by CNBC. Needless to say, the benefits of on-demand manufacturing are crystal clear: reduced costs, faster turnaround times and increased flexibility.

“Manufacturers are turning to on-demand production to reduce inventory, decrease lead times, and increase production efficiency,” reports IndustryWeek and with the rise of on-demand manufacturing, companies can now quickly respond to changing customer demands and market trends.

The Flexibility of 3D Printing

When it comes to 3D printing, one of its most attractive factors is how flexible it is compared to traditional manufacturing processes. It takes far less time and resources to produce complex parts or products than it does with conventional methods such as injection molding or machining – all without sacrificing quality or integrity.

This makes it much easier for companies to quickly pivot their supply chain strategies if needed or experiment with different designs without breaking the bank. Not only that, but production can be localized much more easily than before since parts don’t have to be shipped from all over the world – instead they can just be printed wherever they’re needed most!

Tremendous Cost Savings

Another major benefit of using 3D printing within a supply chain is cost savings. By leveraging this technology, businesses are able to reduce overhead costs associated with production since they don’t need expensive machines or large factories anymore – just a printer!

Additionally, due to its customizable nature, companies also save money by being able to produce exactly what’s needed rather than ordering in bulk which often leads them to pay for unnecessary materials and extra labor hours.

As a result of these cost savings, businesses have more capital available which can then be invested into other areas such as research and development or marketing campaigns – further positioning them as competitive contenders in their respective industries!

3D Printing Of Consumer Products

One key point regarding how 3D printing could impact supply chains by 2024 concerns consumer products themselves: what if instead of having items shipped from overseas factories where labor costs are low we could print them right here at home?

3D printing of consumer products would significantly reduce our reliance on overseas factories while also providing consumers with customizable options (think personalized mugs) that were previously unavailable through traditional methods like injection molding. It’s often overlooked by many but this concept has already taken off in some industries – think eyeglasses frames made out of plastic filament!

To everyone’s surprise, these products are becoming increasingly popular among consumers who value convenience and customization when making buying decisions – needless to say there’s no doubt we’ll see an uptick in demand for other products made with FDM printers over the course of 2023-2024 as well!

Sustainability Benefits

Finally, we come back around full circle towards sustainability benefits associated with 3D printing and on demand printing: reducing waste caused by unused materials (think plastic filament) while simultaneously cutting down on carbon emissions related transportation costs (since parts don’t have to travel long distances anymore).

To put things into perspective if you think about how much energy goes into producing items conventionally versus producing them via additive manufacturing, then it becomes clear why so many people are now turning towards this revolutionary technology – especially considering its potential applications within environmentally friendly initiatives like reusing plastics for example!

There’s no doubt that 3D printing will continue making waves across multiple industries throughout 2023-2024 – particularly when it comes down to improving existing supply chain models based upon customer preference and demand, while simultaneously cutting down on environmental costs associated with traditional production methods like injection molding or machining.

What might make you wonder though is why haven’t more companies jumped onboard yet? With its impressive list of advantages including flexibility, cost savings and sustainability benefits, what better time than now to start introducing additive manufacturing into your own business model?

The potential applications for utilizing three dimensional printers within existing supply chains are truly mind-boggling – from reduced costs associated with production processes through localizing output centers all the way up to sustainable practices related to reducing carbon emissions transportation needs.

Indeed, there’s something here everyone will benefit from moving forward into the future!