To stay successful, modern businesses must possess comprehensive knowledge of supply chain management. Yet, successfully navigating the intricate network of interrelated workflows and stakeholders can be overwhelming. Enter ERP systems for supply chain management, helping companies thrive and prosper.

Check out this must read comprehensive guide to ERP in Supply Chain.

The essence of ERP systems

Statista, a trusted source for market research, predicts that by 2026, the global ERP software market will reach a value of around $101 billion, including solutions for logistics.

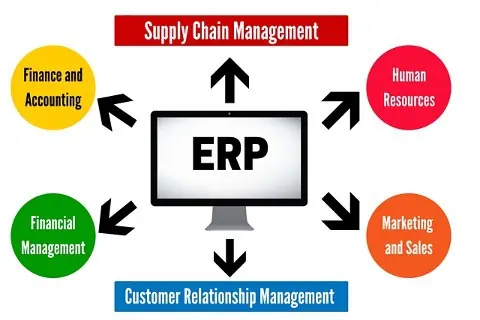

Such products are indispensable for efficient operations. They possess all the important components to carry out industry-specific tasks with precision.

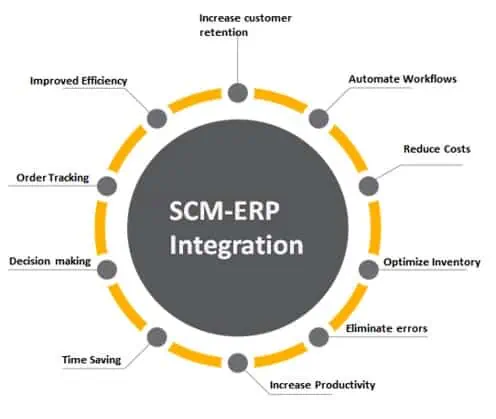

ERPs allow for smoother workflows, fewer complexities, and enhanced teamwork. Automation of tasks and data integration allow digital products to conserve time and avoid errors.

Cutting-edge solutions help companies to adapt to dynamic market conditions, fostering agility and operational excellence.

Assessing your current supply chain landscape

First, you should evaluate your current state of affairs thoroughly. Thus, you will gain valuable knowledge of the main processes and features and locate strong and weak points that can be enhanced.

Armed with this important information, you can elaborate targeted strategies and imply the necessary tools to enhance the entire work process. Robust tools will aid you in having immediate awareness of your supply chain, allowing for better tracking of essential metrics like stockpiles and order completion.

Defining clear optimization objectives

Establishing concrete goals plays a critical role in bringing about real change.

First, evaluate your current performance and find out specific pain points or areas for enhancement. Depending on what your enterprise needs, the objectives may be different. But some of the more popular ones include increasing accuracy of operations, shortening the time it takes for orders to be fulfilled, changing stock levels, improving collaboration with suppliers, and making customers happy.

Moreover, you should communicate objectives to your employees and partners. Involving key players and promoting teamwork can ensure that everyone is striving for the same goals.

Finding the right digital product

Deciding on an efficient software solution is a vital choice that can drastically influence your operations. Assess different options and see which ones possess the qualities you require.

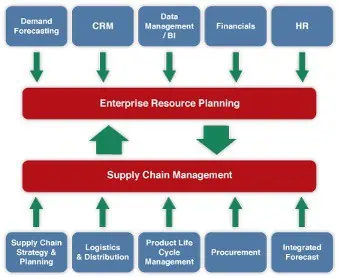

- Integration capabilities are crucial, as an efficient solution must easily bring together information from various departments. With such functionality, you will enjoy impeccable workflows.

- Additionally, a shared database is necessary to secure instant access to all participants, regardless of the module they’re working with.

- Automation allows specialists to make cross-functional workflows faster, lessening the amount of manual labor.

- Well-oiled analytics and reporting will give you the necessary information to make the right choices.

- Lastly, put an emphasis on security features to protect sensitive information.

Assess the cost of a solution, with customizations, the quantity of users, and necessary modules in mind. Costs can vary significantly, with small businesses spending an average of $1,740 per month, while enterprises may incur expenses of $9,330 per month.

Integrating an ERP in existing workflows

Unlocking the full potential of your company relies heavily on this pivotal step. By seamlessly integrating software products, you can enter a realm of unprecedented efficiency, heightened visibility, and enhanced workflows that permeate every aspect of your ecosystem.

- Assess compatibility

Before embarking on integration endeavors, conduct a thorough evaluation of the compatibility between your selected system and your current software infrastructure, as well as your distinct operational workflows. Scrutinize the areas of convergence and pinpoint any potential discrepancies that necessitate attention and resolution.

- Outline the goals of integration

Figure out which supply chain activities, systems, and data need to be integrated with the ERP system. Areas of concern include sourcing, stock control, order processing, demand forecasting, and other relevant topics. This move will help you concentrate on the integration plans and use resources efficiently to obtain top performance.

- Establish data exchange protocols

Successful integration hinges on this critical aspect. Analyze the structure, frequency, and security measures related to data exchange between your current systems and the ERP platform.

- Collaborate with stakeholders

Engage essential staff members from different departments to grasp their distinct needs and viewpoints. By incorporating their input in the initial stages, you can tackle potential obstacles, alleviate resistance to change, and facilitate integration.

- Plan for change management

Create a comprehensive plan for managing change to successfully go through this transition. Make sure everyone is aware of the benefits and drawbacks of the integration, give instruction and help, and take care of any fears or resistance that might show up.

- Examine performance and assess results

Once the integration is finished, have a system in place to monitor and assess performance. Establish KPIs to measure the effectiveness and output of the combined operations. Assess the impact on crucial metrics like lead times, inventory turnover, and customer satisfaction regularly.

Enhancing inventory management

Leveraging an ERP platform gives you a chance to enhance your inventory practices, improve their precision, and optimize the workflows across various departments.

- Monitoring stocks

By using the latest software, organizations can keep track of their inventory levels in different areas in real time. A strong tracking system makes it easier to recognize when stock is low, allowing for quick action such as automated restocking or adjusting inventory distribution. Making use of instantaneous data can help companies keep the ideal amount of stock, avoiding the dangers caused by not having enough or having too much.

- Making accurate projections of demand

Advanced algorithms that investigate past sales data and current market trends are employed in cutting-edge solutions for generating dependable predictions. Utilizing a data-based approach empowers companies to accurately forecast future demand, allowing them to adjust stock levels to match customer needs, and thus avoid any risks of overstocking or missed sales due to inadequate inventory. Developing forecasting capabilities increases operational efficiency, allowing for smaller inventories and still meeting customer service standards.

- Introducing an automated inventory ordering process

ERP systems automate and streamline the whole inventory procurement procedure, getting rid of the need for manual labor and reducing the chance of mistakes. This includes speeding up tasks like creating purchase orders, sending them to vendors, taking in goods, and making sure that stock information is up to date. This automation eliminates the risk of delays, increases accuracy, and optimizes the use of resources, resulting in time and effort savings for inventory managers.

- Ensuring regular data integration

Streamlined systems make sure all departments have up-to-date data, making it easy for teams to share information. This integration allows sales teams to view real-time stock availability, making sure they can keep customer promises and avoid any potential disappointment. What’s more, finance teams can quickly access the current cost data for each sold item, which makes it easier to prepare accurate financial reports and analyses. Keeping information in sync helps to avoid any differences, encourages teamwork, and allows for more informed decisions, leading to a greater sense of unity and collaboration in the workplace.

Utilizing ERP to bolster demand forecasting and planning

Examining past data allows for knowledgeable decision-making when it comes to supply chain management, inventory control, and understanding the flow of goods through demand forecasting. Cutting-edge software is necessary to make sure demand forecasts are accurate, inventory is managed well, warehouse needs are understood, staffing is appropriate, budgets are allocated properly, and marketing strategies are effective.

Supply chain management software usually has powerful features for forecasting demand, which can help companies accurately predict customer demand and make sensible decisions. This includes generating various types of reports that provide valuable insights to business owners, helping them understand market trends, optimize inventory levels, and plan their operations accordingly.

- Order of inventory report

This report puts products in order of their gross margin from highest to lowest over a certain period and shows how profitable they are when compared to their storage costs. Companies can use this report to recognize items that take up too much room in their warehouses and have too much worth on their financial statements in comparison to their contribution to overall profits. This data is beneficial for controlling inventory and boosting earnings.

- Inventory “hits” report

This report evaluates the frequency of a product appearing on invoices, with a particular focus on products that don’t move as quickly but still constitute a significant portion of the stock. It is helpful in recognizing products with irregular demand patterns, and it helps businesses modify their inventory control tactics as necessary.

- Average daily sales report

These give insights into average daily sales over different periods (e.g., last month, last quarter, last year). Companies can use these reports to detect patterns and specific areas where restocking levels and purchasing activities may need alteration, and adopt sound strategies to optimize inventory planning and control.

Making operations fully transparent

Attaining live visibility into operations plays a pivotal role in the entire process. Here are the valuable contributions provided by a good ERP solution:

- Live monitoring

Obtaining recent information on logistics and stock can be difficult for many businesses, making it hard for them to make decisions. However, with an appropriate technological solution, organizations can swiftly access real-time visibility into their supply chain operations. This enables them to spot and resolve any problems quickly. An efficient system enables thorough tracking of inventory levels throughout multiple worldwide distribution centers, encouraging increased governance and synchronization.

- Optimal warehouse management

Adequate software solutions are necessary to effectively manage warehouses in multiple locations. ERP systems specializing in supply chain management offer businesses an all-encompassing view of their warehouse operations, ensuring transparency and preventing problems like overordering or running low on inventory. To maximize inventory and make the warehouse more efficient, businesses can update their supply chain processes, making sure they work well.

- Practical insights

By utilizing the latest systems, companies obtain access to advanced resources to analyze inventory and supply chain data, which produces valuable findings. Companies can use this data-based approach to anticipate customer needs, recognize potential issues, and take initiative to avoid them. Companies can use accurate and practical information to strategically plan and make wise decisions to maximize their supply chain operations.

Improving order completion and delivery operations

Automation features make order processing a breeze through an efficient system. It accurately and quickly processes customer orders, invoices, and payments.

Procuring and obtaining items from suppliers becomes effortless with an efficient system in place. A well-functioning solution oversees the entire procurement process, automating the tracking and evaluation of quantities upon arrival to ensure the appropriate quantity and quality are received. Moreover, it facilitates efficient placement of items within the warehouse, optimizing accessibility and retrieval speed.

By employing real-time order tracking, companies can obtain instant visibility into the status of their orders, including comprehensive shipment details and confirmation of successful deliveries. This functionality plays a vital role in detecting any potential bottlenecks in the fulfillment process and ensures timely and dependable delivery of orders.

Other important features to mention are efficient picking strategies, seamless shipping, and easy return mechanisms.

Applying data analytics to ongoing refinement

Harnessing the power of ERP data analytics is essential for ongoing enhancements in supply chain management. By scrutinizing extensive data sets, ERP software empowers enterprises to uncover patterns, predict customer demand, and dynamically optimize inventory levels.

This enables timely identification of areas that need attention and proactive mitigation of risks, ensuring seamless operations and customer satisfaction. The exchange of insights derived from data-driven analysis promotes collaborative efforts and adaptability throughout the supply chain, empowering businesses to make well-informed decisions and elevate overall efficiency.

Keeping up with performance and changing strategies

ERP systems empower businesses with a comprehensive overview of their operations, enabling them to proactively identify potential issues, streamline processes, and enhance efficiency. By harnessing these insights, companies can anticipate shifting customer demands, promptly respond to market conditions, and maintain a competitive edge in the dynamic business landscape.

With access to robust data and analytics, ERP systems equip organizations with the means to measure KPIs, pinpoint areas for improvement, and adapt strategies as necessary. By leveraging real-time information, businesses can make data-driven decisions, optimize their supply chains, and enhance overall performance. This proactive approach enables companies to anticipate changes, sustain momentum, and uncover new avenues for growth.

Wrapping up

The incorporation of ERP systems in supply chain management has transformed the operational landscape for businesses, providing them with an opportunity to attain streamlined workflows and achieve remarkable efficiencies.

Leveraging cutting-edge solutions provided by prominent supply chain management software companies, organizations can unlock unparalleled transparency into their operations, optimize inventory control, streamline order fulfillment procedures, and make informed decisions based on data insights.

Innovative digital solutions assist businesses in navigating the intricacies of the global market, enabling them to swiftly adapt to evolving customer demands and gain a competitive advantage. With robust systems as the foundation, modern companies can embark on a journey of continuous enhancement and expansion, propelling their growth in a dynamic business environment.