Is your Supply Chain reactive, always fire fighting and dealing with new problems every hour and every day?

Or is your Supply Chain proactive, having defined and implemented the strategies necessary to create a more robust and resilient Supply Chain, less amenable to daily disruptions and surprises?

In a recent article, The Reactive vs Proactive Supply Chain! Which Will Prevail? we discussed this problem and state of companies around the world.

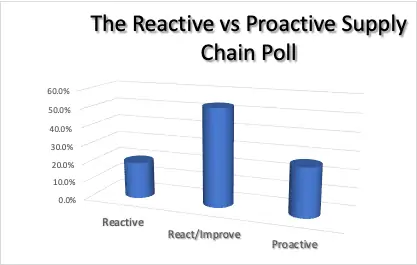

We polled our readers to find out where their companies stand in this regard. Here are the results!

A Recap

The global Coronavirus pandemic proved that virtually every Supply Chain, no matter how sophisticated or how streamlined, is vulnerable to disruption and continuity of supply issues. The ramifications and impacts of these vulnerabilities is still being felt, and will be for some time to come.

And for those who have worked in Supply Chain, dealing with issues and problems is not new news. Quality issues, delivery delays, equipment and capacity constraints, system and process problems, customer demand shifts, part and material shortages all conspire to disrupt the best laid plans of the best Supply Chain professionals.

Now while there are Supply Chain people who thrive in this reactive, adrenaline-rush environment, it is generally necessary activity but not desired activity. Time would be much better spent working on more proactive, more strategic and more intellectually demanding endeavours.

Still there are those who say they have no time to spend on strategic efforts. They are too busy dealing with the day to day fires and disasters to do anything else. They are stuck in an endless downward spiral. They don’t take the time to make things better so they are destined to spend all of their time dealing with things as they continue to get worse. It’s an endless cycle that goes nowhere.

Other companies take a different approach. They are more proactive and strategic. They want to create more robustness in their Supply Chains to make them better able to withstand and mitigate the incidence of day to day problems. There will always be problems that emerge. That is unavoidable. But these proactive companies are able to resolve them faster and then quickly get back to further increasing their resilience.

The proactive Supply Chain requires leadership first and foremost. Leaders must be able to create a vision and strategy, and then carve out the time for their employees to execute that strategy.

The very idea of wanting to work in an organization that is more proactive and forward thinking seems intuitive. After all, who wants to work in a company dealing with disasters all of the time.

But yet there are companies who, for one reason or another, operate their businesses reactively with no regard to making things better for their customers, their employees, and all of their stakeholders.

The reactive companies certainly lack leadership, they lack visioning, and they lack strategy. Just ask their employees. The employees very often know what is going wrong, why it is going wrong, and what can be done to make strong improvements. But if you don’t have leadership they aren’t listening to employees and things continue to go awry.

It is in this context that we polled our readers to find out where their organizations were in this regard. So let’s get to the results:

Our Proactive Supply Chain Poll Results

In the interest of creating a clear distinction in the results we asked our question and provided only 3 possible responses. The question was:

“Is your Supply Chain Reactive and always fixing problems or Proactive and trying to create a more robust environment?”

The possible responses were:

- Reactive

- Reactive but improving

- Proactive

This seems pretty straight forward, especially as we have all just come through a few very difficult years with the pandemic, in which Supply Chain has been front and centre of every company, every industry and institution, and every person unlike ever before in history.

Over 20% of our Proactive Supply Chain Poll results respondents felt that they were working in a company which was entirely reactive, with no efforts afoot to make things better. 53% of our respondents were working in companies that were reactive but were taking steps to make things better in some form. And 27% of our respondents felt they were working in a proactive Supply Chain company.

It is disappointing, but perhaps not surprising, that 1 in 5 companies have no hope but to continue to work in a reactive mode. They obviously lack leadership and resources and intent. These companies are highly vulnerable to future disruptions which will jeopardize their very survival.

It is more encouraging that over half of companies, while they are still in a reactive operating mode, are taking steps to make improvements. Time will tell whether those improvements are minor and incremental or whether they are significant and transformative. The important point is that they are somewhere on the journey to create a better Supply Chain and operating environment for everyone involved.

And it is commendable that another quarter of our companies are already working in a proactive mode. There is always room for improvement so the test will be whether they continue to refine their approach. Even companies that practiced Just-In-Time practices were brought down by the pandemic, proving that even the very best proactive companies need to continuously improve.

Conclusion

The process of creating a proactive, robust and resilient Supply Chain is never done. And even if you haven’t even begun that process, there is always hope and opportunity that you can move forward. The only real problem is if you never make, or intend to make, any steps forward at all.

The world needs more robust and proactive Supply Chains. There will always be another disaster, whether localized, regional or global. There will always be day to day issues that crop up.

Wouldn’t you prefer to work in a company that has progressed and taken steps to mitigate those bad incidents, and taken steps to resolve them quickly when they occur?

Every professional, every citizen, every company, every industry, every institution and every government want Supply Chains to be more proactive and robust.

And as per our poll results, it is good to see that so many are on their way, and we hope that the few who are not will get on board before it is too late for them.