A lot has changed over the years in regard to distribution centers.

What once was a fancy term for “warehouse,” a storage place for merchandise until it could make its way to retail shelves, the modern distribution center has become one of the critical aspects of determining a retail business’ success or failure in the age of eCommerce.

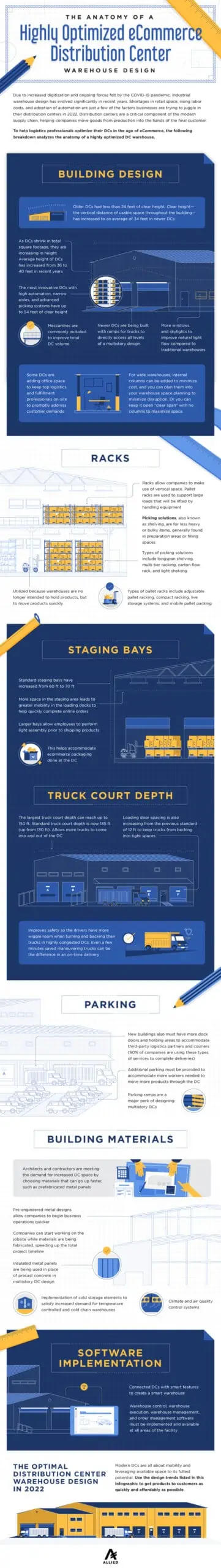

Modern distribution center design must be able to accommodate for a plethora of factors, including:

- Widespread customer demand for fast and free delivery

- Increased traffic from delivery trucks and third party couriers

- Integration of automation and connected features to seamlessly track inventory and process orders and returns

- Sustainable design to comply with increasing environmental awareness of the public and government agencies

And the demands can get even more nuanced, depending on the business’ particular industry.

To further complicate matters, optimized ecommerce warehouse design must occur in the face of unprecedented increases in the cost of labor, real estate, and building materials.

So let’s take a look at how firms are tackling DC design.

To start with, the average floor space of modern DCs is shrinking. This is not necessarily because large, mega warehouses are disappearing entirely–some companies still have the occasional 500,000+ square foot behemoth serving as a central distribution hub–but because smaller DCs are popping up closer to large population centers to help tackle challenging last mile delivery scenarios.

And while the average amount of DC floor space is shrinking, that does not mean facilities are getting smaller. Fifty years ago, the average warehouse height was a mere 24 feet. Today, the average height of a DC is around 34 feet.

This allows eCommerce retailers to install more racks and shelves into their DC–referred to as light storage space–which makes for easier picking to more rapidly move products through the supply chain and to their final destination.

Increasing the vertical height in contemporary DCs also allows for better mobilization of floor space. Facilities cannot be slowed down by clogged aisles and cramped work areas. Forklifts and other types of machinery must have an unencumbered path to stock and pick shelves.

Workers must be able to deftly maneuver throughout the DC, performing light assembly on some types of products and packaging merchandise for delivery. In conformance with this trend, the average size of staging bays has increased by roughly 10 square feet in recent years to increase mobilization in packing and facilitate easy loading for speedy deliveries.

And improved mobility is not just a trend on the DC floor.

Truck courts are increasing in depth, now up to as much as 150 feet in some facilities. This gives trucks more wiggle room to navigate high-traffic DCs that see a constant stream of delivery vehicles throughout the day. This coincides with a general increase in the number of loading doors that feature additional space between docks–all designed with an eye toward greater mobility to churn more online orders per hour.

Due to this evolution of DC design and the unique demands created by the eCommerce explosion, greater attention than ever is being placed on the type of materials used in building DCs.

A cold concrete box no longer gets the job done.

Facilities are incorporating large, low-e windows into their DCs to improve lightflow, increase worker mood, and reduce electricity consumption. Acoustic sound clouds are being installed to prevent unwanted noise transfer from one area of the DC to another. Modular partitions are being utilized to create office space so that logistics professionals can solve complicated problems on site.

However, the most prevalent material trend is the use of steel buildings for eCommerce Distribution Centre solutions.

Structural metal buildings offer numerous benefits for DC optimization. They can span well over 100 feet without requiring support from pillars or beams. This “clear span” allows firms to utilize every ounce of floor space possible, providing an unencumbered surface for adding light storage and moving throughout the facility.

Metal facilities are also desirable for their ease of construction. Because companies are having to rapidly increase their DC footprint to satisfy increased eCommerce orders, time lost during the construction phase can severely impact profits. As most structural metal facilities are fabricated offsite in easy-to-erect kits, a steel DC can go from breaking ground to operational in a matter of a few months, allowing for increased order volume without a hitch.

Finally, steel facilities are increasing in popularity as an eCommerce DC solution due to their elite durability, ease of maintenance, and energy efficiency features.

As eCommerce continues to grow in an increasingly digitized society, contemporary DC design must evolve and adapt to protect retail business’ profits.

For a more detailed breakdown of how eCommerce businesses optimize their eCommerce distribution centre, take a look at the following infographic that explains each component in detail.