Factory floor operations are diverse and vary hugely in size. Most factories have unique outputs that take an idea, make it, and get it out to consumers. It is on the factory floor where several operations take place to ensure the efficient production of goods.

Many people work on the factory floor, and there are many steps on any given production line; this being so, a high level of efficiency is needed in order to ensure that the production line runs smoothly. Managers are always looking for ways to optimize operations, prevent delays, and ensure their staff are well trained.

This blog will give those in charge of factory floor operations some tips to maximize their workflow, help reduce waste, and improve efficiency.

Include Waste Recycling into Operations

Reducing waste is one way in which those on the factory floor can improve operations. Although most manufacturing facilities aim to reduce waste as much as possible, they could do more to make a concerted effort to increase recycling processes.

For example, many of the materials used in manufacturing, such as paper, plastics, and metals, can be recycled and used again. One way to do this is to ensure you have the best equipment possible to help with any recycling needs; for example, state-of-the-art conveyors designed for sorting systems and recycling.

With this in mind, a website such as fluentconveyors.com is a great company who will be able to find specialized equipment to help with your factory recycling needs.

Prevent Order Delays

Delays on the production line can have a ripple effect, meaning that there is often a backlog of goods and orders, leading to unhappy and unsatisfied customers. In order to prevent delays at the factory level, those in charge need to have a contingency plan.

First, they will need to create a manufacturing timeline, which is an invaluable tool for this industry. They will need to chart different milestones, potential delays, and other essential factors onto their timeline before any operations begin.

Having this sort of system in place before operations begin will enable factory floor managers to be prepared for any hiccough and create contingency plans instead. For example, they should plan for interruptions such as a machine breaking or a backlog in one section of production.

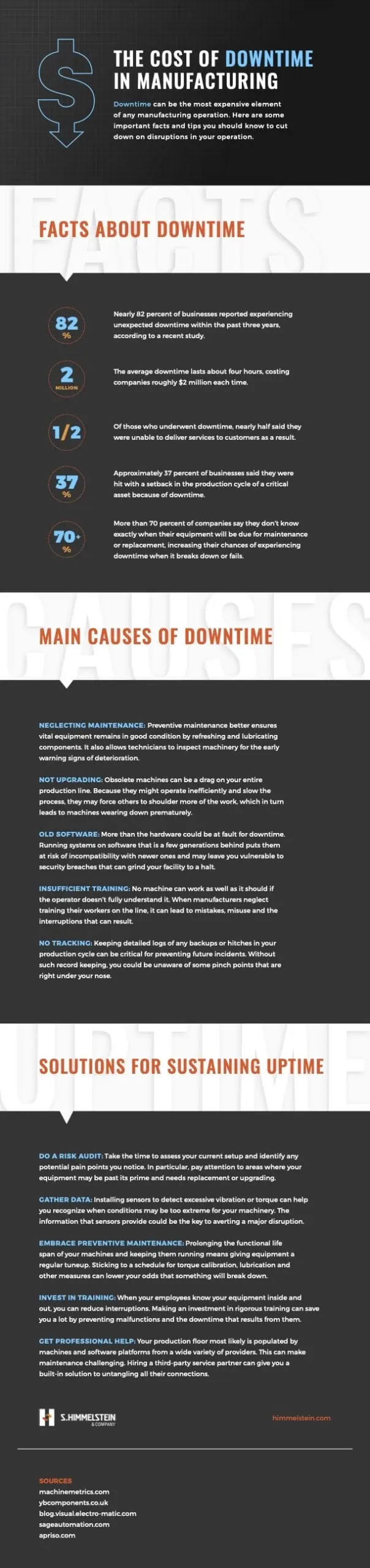

Optimizing your factory floor operations includes minimizing downtime. To learn more on how costly downtime is to your factory, please see the tips below.

Train Your Staff

Ensuring that all employees are trained to the highest degree is extremely important on any factory floor. Employees who are skilled workers will know what they are doing and how to operate large automated machinery.

Having knowledge on correct operations will optimize any workflow, whether the factory space is big or small. This can have a very positive ripple effect on the production of goods, and you are likely to see an increase in goods and a decrease in labour time.

Specify Shipping Dates Early

The final requirement for optimizing factory floor operations is for managers to specify their shipping dates early. Again, being transparent with importers and shipping companies about your expectations and timings can help to improve efficiency.