3D printing is a process that involves creating a three-dimensional physical object from a digital design. The said design is made using CAD (computer-aided design) software, and is used as a blueprint for professional 3D printers.

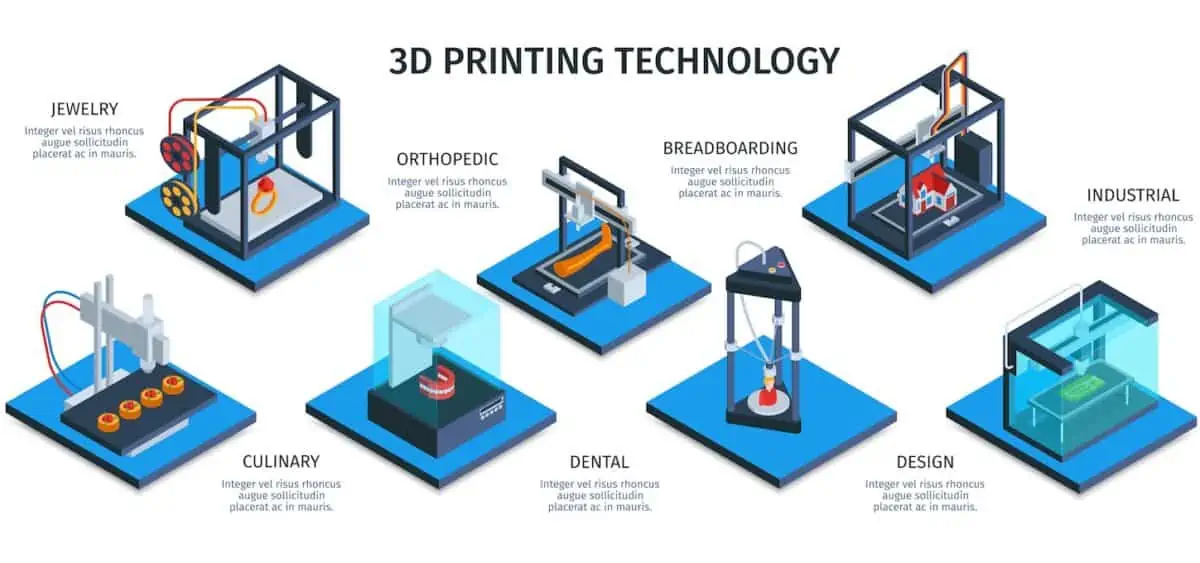

3D printing is used in various industries, including medical, food, and architecture, to mention a few. This article will look into the industrial applications of 3D printing in the said sectors. Keep reading to learn more.

3D Printing Technologies

There are three main types of technology used in 3D printing. The first one is melting. Here, materials are heated and melted at high temperatures before being deposited in layers to create a 3D object. It’s one of the most common types of 3D printing and is used to create parts and products in a variety of materials, including plastics, metals, and composites. The high temperatures used are from electric arcs, lasers, and electron beams.

The second technology is sintering, which is used for 3D metal printing. Here, materials are heated to create high-resolution objects. Metal powder is used for direct metal laser sintering, and thermoplastic powder for selective laser sintering.

The third one is stereolithography, which involves the use of a UV laser to selectively cure liquid photopolymer resin layer by layer to build a 3D model. It’s the oldest form of 3D printing and is considered the most accurate of all 3D printing processes

With these technologies, you can do different types of printing, such as titanium 3d printing, which is used in medical, automotive, and even aerospace industries. It utilizes the Ti6A1-4V alloy, known for its mechanical strength, strong resistance to corrosion, and a robust strength to weight ratio.

Industrial Applications Of 3D Printing

Here are some of the ways 3D printing is used in different industrial applications:

1. Food Industry

The food industry has also taken advantage of 3D printing and is using this technology in the following ways:

Improving Food Packaging

High-quality packaging matters as it protects food products from external damage, and provides consumers with information regarding the ingredients used, as well as their nutritional benefits. Moreover, 3D printing also allows for the creation of food packaging in various shapes and sizes, which can benefit any aesthetics-related objective.

Allowing For Personalized Nutrition

Old age and illnesses can result in a patient needing personalized nutrition. At times, it can be time-consuming to obtain this, especially if it’s for a group of people. However, 3D printing is now used to create food products to meet specific dietary needs suitable for a person’s condition.

For instance, a nursing home in Germany uses 3D printing to create smooth foods, which are made by combining broccoli, mashed peas, and carrots, and, then, thickening them with edible glue. This concoction is fed to the elderly who have chewing difficulty. Due to the success of this project, other facilities in Germany have adopted the same process.

As seen above, you can use 3D printing to improve food packaging or create nutrition-dense products for people suffering from various conditions.

2. Medical Industry

The medical sector uses 3D printing in the following ways:

Making Organ Replicas

With 3D printing, patient-specific organ replicas can be created for doctors to practice on, especially in cases of vital surgeries, such as spinal surgeries and full-face transplants. Besides sharpening their skills, this practice helps speed up surgical procedures, as well as reduce the possibility of trauma in patients.

Producing Surgical Instruments

Some standard instruments used in surgical rooms include scalpel handles, forceps, clamps, and hemostats. These instruments can be produced using 3D printing instead of traditional manufacturing methods, like one-piece forging, which involves shaping metal (eg. titanium) into the desired shape by hitting or pressing.

Unlike one-piece forging, 3D printing can produce many instruments within a short amount of time. Also, it’s easy to make instruments in small, precise shapes. Such tools are used to operate on small body parts without making unnecessary big cuts, causing extra damage to the patient.

Furthermore, producing surgical instruments through 3D printing is more cost-efficient than traditional manufacturing methods.

Custom-Making Prosthetics

Unfortunately, one may be involved in an accident or have a medical condition that necessitates the use of prosthetics. These are artificial body parts used in cases of missing body parts or non-functioning ones.

Before the adoption of 3D printing, a patient had to wait for weeks or even months before they get the prosthetics they need. However, with this technology, prosthetics have become so much more accessible, at more affordable prices.

However, one might wonder whether the functionality of prosthetics made using 3D printing is the same as those produced using traditional methods, like conventional fabrication. The answer is yes; you can rely on them when it comes to functionality.

3D printing technology has made it easier for the medical industry to create equipment, as well as organ replicas and prosthetics, which used to take much longer to manufacture using traditional methods.

3. Architecture Industry

The architecture industry hasn’t been left behind in terms of 3D printing application. Here are some of the ways this technology is used in this sector:

Creating Concept Models

The first step in an architectural project is coming up with a concept model, which is used to visualize the design of a project. One of the ways of creating a concept model is making it by hand. However, this approach can be tedious, especially if complicated geometrics are involved.

The other approach is using 3D printing. It makes the process of creating concept models more efficient as it takes a shorter time to make changes, and provides a range of materials and colors you can incorporate.

Interior Designing

Interior design involves coming up with ways to improve a room’s aesthetics. With 3D printing, you can create detailed and complex furnishings and other parts faster. Also, if you need small decorative pieces, you can use 3D printing to prototype them. That’ll help you save on labor costs and reduce waste materials.

As discussed above, 3D printing has allowed for quicker creation of concept models, and has made interior designing processes more efficient.

Summing It Up

Times have changed, and how things are done has also changed, thanks to technological advancement. One of the modern technologies used in multiple industries today is 3D printing, and it offers a number of benefits.

Some of these advantages for industrial applications include faster production, improved quality, reduced risks, and affordability.